What is Metal Stamping? How Does It Work?

Metal stamping services are important for various industries. In the US alone, there are thousands of companies that offer metal stamping services to deliver components for industries such as medical, aerospace, automotive, and many more.

As the global market evolves, the need for metal stamping services continues to increase. In this post, we focus on metal stamping basics, types of metal stamping and their applications, the flaws or defects caused during the process, and inspection solutions for the defects – AOI (Nova Series).

What is Metal Stamping?

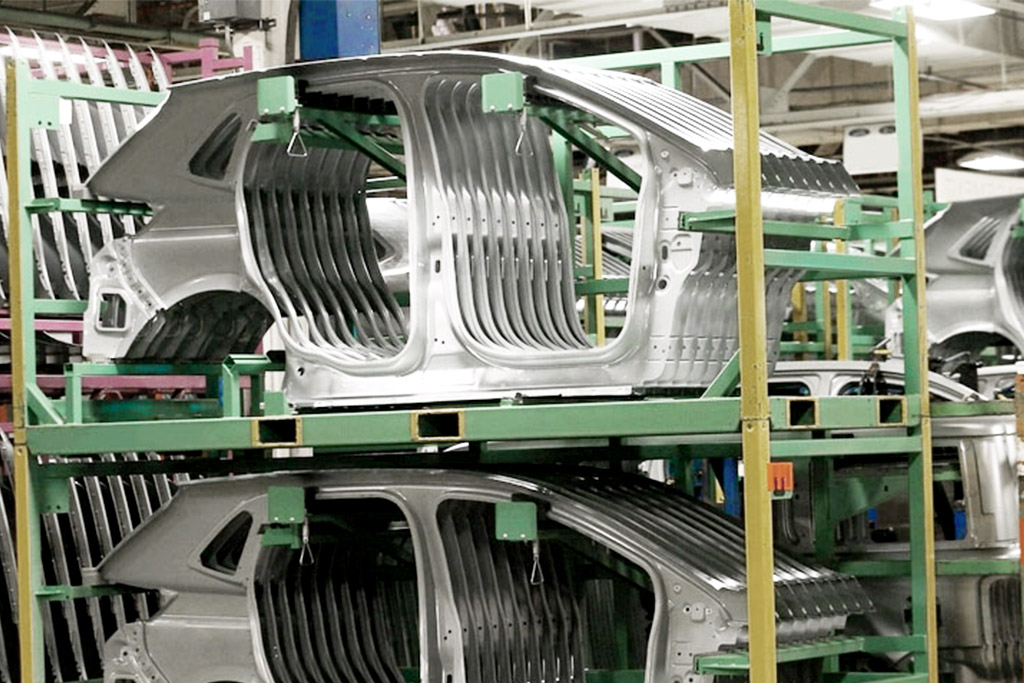

Metal stamping is a cold-forming manufacturing process used to transform flat metal sheets into specific shapes. This complex process makes use of dies and stamping presses to convert metal into a new shape.

During this process, the material will be subjected to pressure that will shape and shear the material into the desired shape. Metal stamping is widely used in production facilities and metal fabricators offering stamping services.

It is a fast, highly durable, and cost-effective solution for large-quantity manufacturing needs for both short- or long-term production runs. Metal stamping may consist of one or more metal forming techniques, such as blanking, bending, punching, coining, flanging, and embossing.

Metal stamping machines may do more than just stamping. For instance, they can cast, punch, cut, and shape metal sheets. However, before forming the material, stamping professionals must design the tooling machine via CAD/CAM/EDM/CNC engineering technology.

EDM (Electrical discharge machining) and CAD (Computer-aided design) ensure accuracy. CAM ensures that each punch and bend maintains proper clearance, hence, optimal part quality. CNC (Computer numerically controlled) offers high precision and repeatability for every stamped piece.

Metal Stamping Application

Metal stamping is used in a wide range of applications, particularly those involving 3D (three-dimensional) designs, lettering, or other surface engraving features.

From your cars to your household appliances, chances are you already have a product in your home that has its parts created via metal stamping. For example steering wheel components, horn buttons, and power tools and etc.

Stamped metal components are also in use in the electrical, aerospace, military & defence, lighting, and medical industry.

Types Of Metal Stamping

There are 4 major types of metal stamping techniques:

- Deep Draw Stamping

- Progressive Die Stamping

- Fourslide Stamping

- Short Run Metal Stamping

Metal Stamping Flaws/Defects

Like any other technically demanding environment, sheet metal productivity suffers from an occasional hiccup or two.

There are numerous quality-assurance standards for managing the equipment and the raw materials, but errors can still crop up from time to time.

Look at those mistakes as an opportunity to learn and improve the process, and make the production line more efficient.

Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects.

- Splits and risk of splits

- Minor or severe wrinkles

- Springback

- Excessive thickening or thinning of the sheet during forming

- Incorrect blank shape or/and size

- Incorrect number or process of forming tools

AOI solutions for Metal Fabricators, NOVA Series

Nova Series is a full (Automated Optional Inspection) AOI solution with checking, sorting, and marking capabilities.

The versatile machine is heavily used in the metal fabrication and stamping industry for the inspection of critical metal parts.

Nova Series can practically work on any device that needs precise automated vision inspection. It is used to guarantee that the standard of products is met during the manufacturing process.

Key features of the Nova-metal fabrication AOI

- Dual scan capabilities top & bottom inspection

- Fully automated and connect to the manufacturing process

- Multiple zoom inspection

- Customized tray to fit your inspection products

- Top & bottom inspection

- Metal fabrication & stamping AOI process

- Colour & mono inspection

Find out more about the AOI Nova series of Cortex Robotics, including its key benefits for businesses and users here.

The Bottom Line

Over the years, the demand for metal fabrication has increased throughout the worldwide market. In this regard, custom metal AOI solutions to both residential and commercial clients can be achieved with the Nova Series machine.

Cortex Robotics Sdn Bhd is constantly working to provide the best AOI solutions coupled with a high level of technical support. From prototypes to production runs, our practices are environmentally conscious.

For further information, feel free to get in touch with our specialists.