Description

Our AOI Solutions Supported Plastic Injection Moulding Process

NOVA SERIES

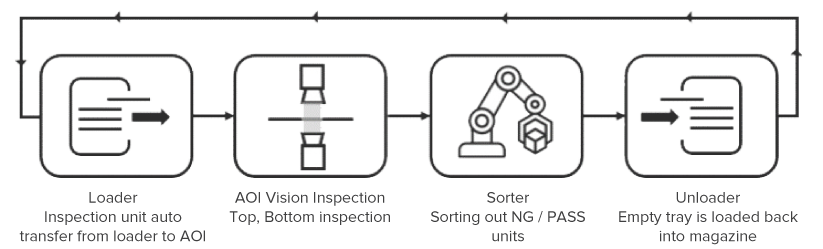

Nova Series – is a FULL AOI solutions with checking, sorting and marking capabilities; heavily use in plastic injection molding Industry for inspection of critical plastic parts.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

Fully automated and connect to the manufacturing process

Customized Tray to fit your inspection products

Top & Bottom Inspection

Multiple Zoom Inspection

Colour & Mono Inspection

Other Features

Marking Modules on defects

Sorting Modules on defects & non defects goods

Generate Report for data analysis

Traceability defect image & unit log for verification

Support Offline/ Off-site Programming

E-Mapping to match tray capacity

Optional Features

Verification Reject Centre for double confirmation on defects before marking

6 Sided Inspection

INSPECTION PRODUCTS

Critical plastic parts such as smart devices parts, semiconductors parts, connectors, medical supplies and etc

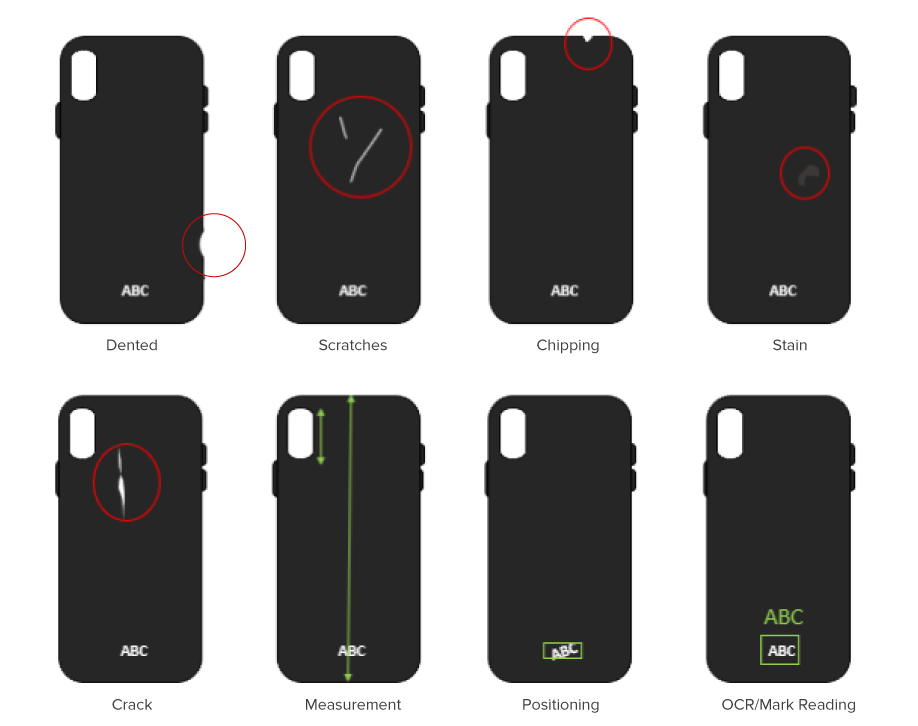

INSPECTION CAPABILITIES

Dented, contamination, chipping, stain, scratches, stain, diameter, height, thickness, Flatness, positioning, absence presence, mark reading