Description

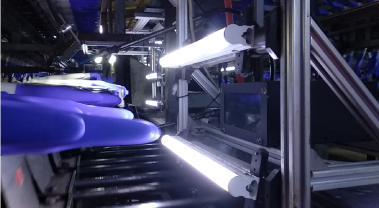

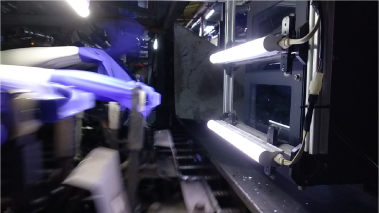

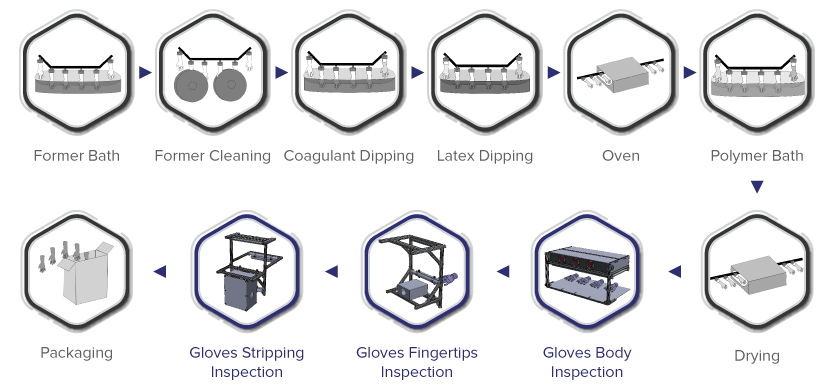

Our AOI Solutions Supported Gloves Manufacturing Process

Former Bath

Former Cleaning

Coagulant Dipping

Latex Dipping

Oven

Polymer Bath

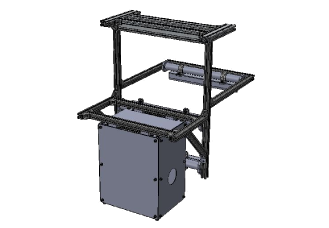

Glove AOI Inspection System

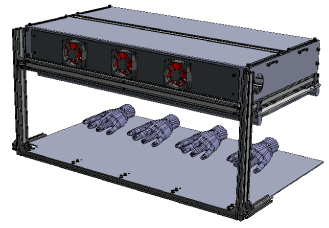

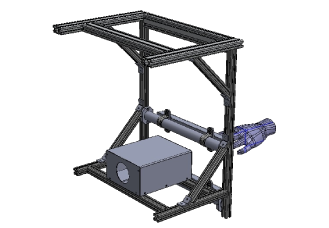

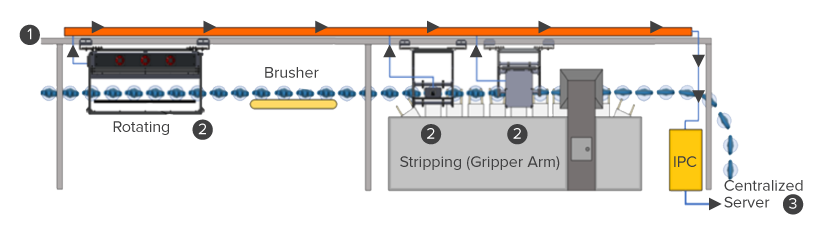

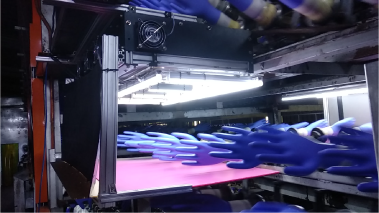

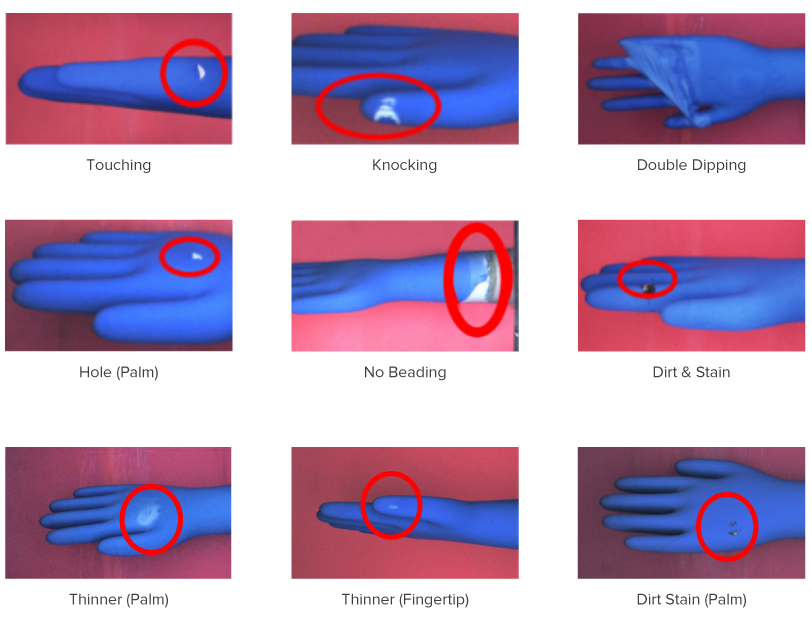

Glove AOI Inspection System is distinctively designed for glove quality inspection during the pre and post-strip processes. It comes with full modules covering the inspection for different part of the gloves. A proven success system serving the market leader in the industry. It allows glove quality inspection to be carried out during the manufacturing process stage following the conveyor speed in the production line. The system has the ability to inspect each of the gloves produced before the packing process replacing human inspection and random inspection. The system will automatically tag the gloves as acceptable or unacceptable based on the inspection results and removed the defective gloves automatically at the end of the production line. The inspection reports generated can be used as quality assurance documents to boost customer confidence and trust. The glove quality inspection system can effectively detect a wider range of defects and enhance the accuracy of the inspection, giving glove manufacturers a competitive edge in precision, efficiency, quality, and manufacturing costs.

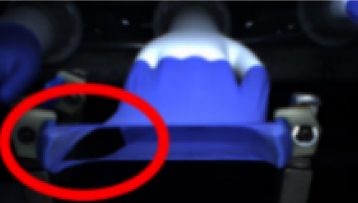

Pre Station Vision System

Inspection on the 360 degree on the body of the gloves

Finger Tip Station Vision System

Inspection on the fingertip of the gloves

Post Station Vision System

Inspection on the wrist while stripping process

BENEFITS OF AOI INSPECTION

To Business

Full Inspection

360 Degree inspection

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

360-degree full inspection from fingertip to body, body to former.

1. Inspection is on the fly connected to the manufacturing process

2. The system is fitted into the machine

3. The system share one processing station (centralized server)

INSPECTION PRODUCTS

Suitable for Rubber, Latex & Nitrile glove

INSPECTION CAPABILITIES

Pre-Station Vision Inspection

INSPECTION CAPABILITIES

Finger Tip Station Vision Inspection