Description

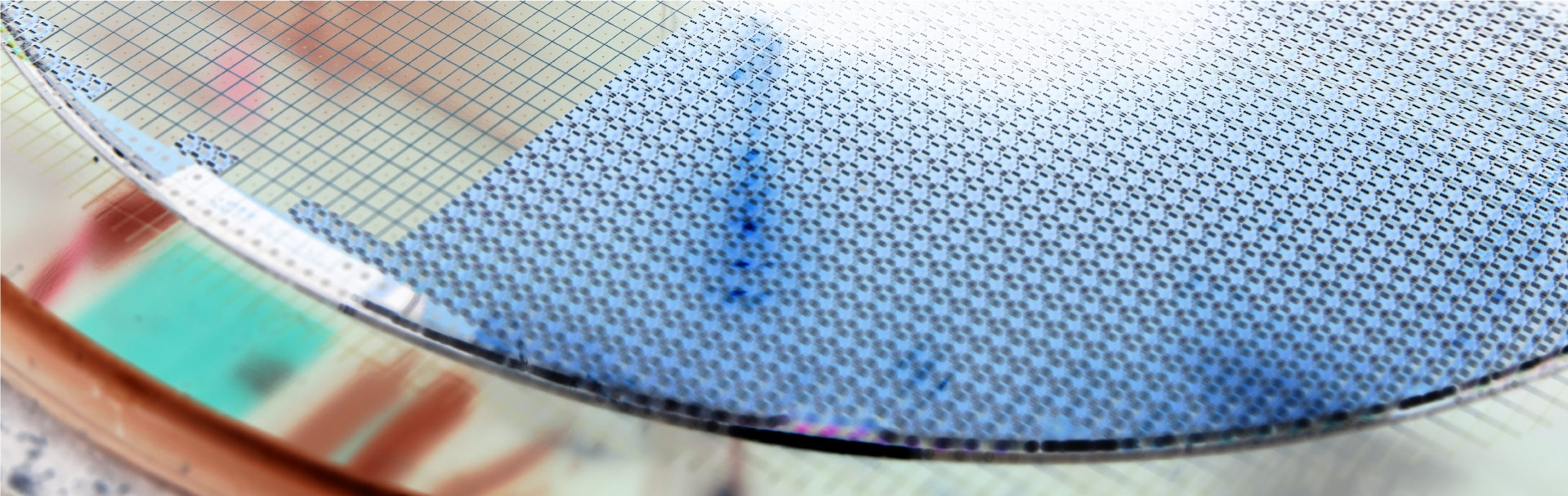

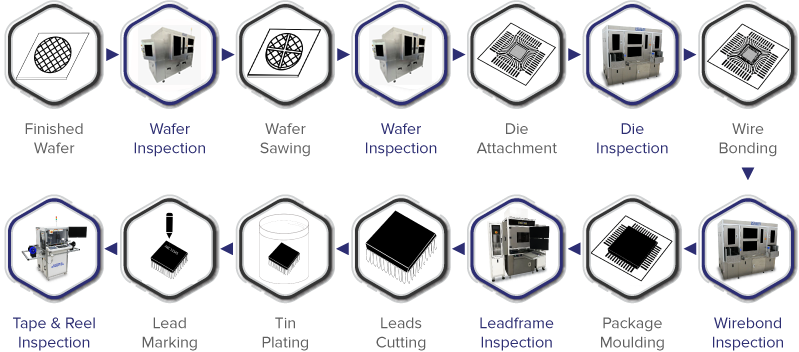

Our AOI Solutions Supported the Backend of Semiconductor Manufacturing Process

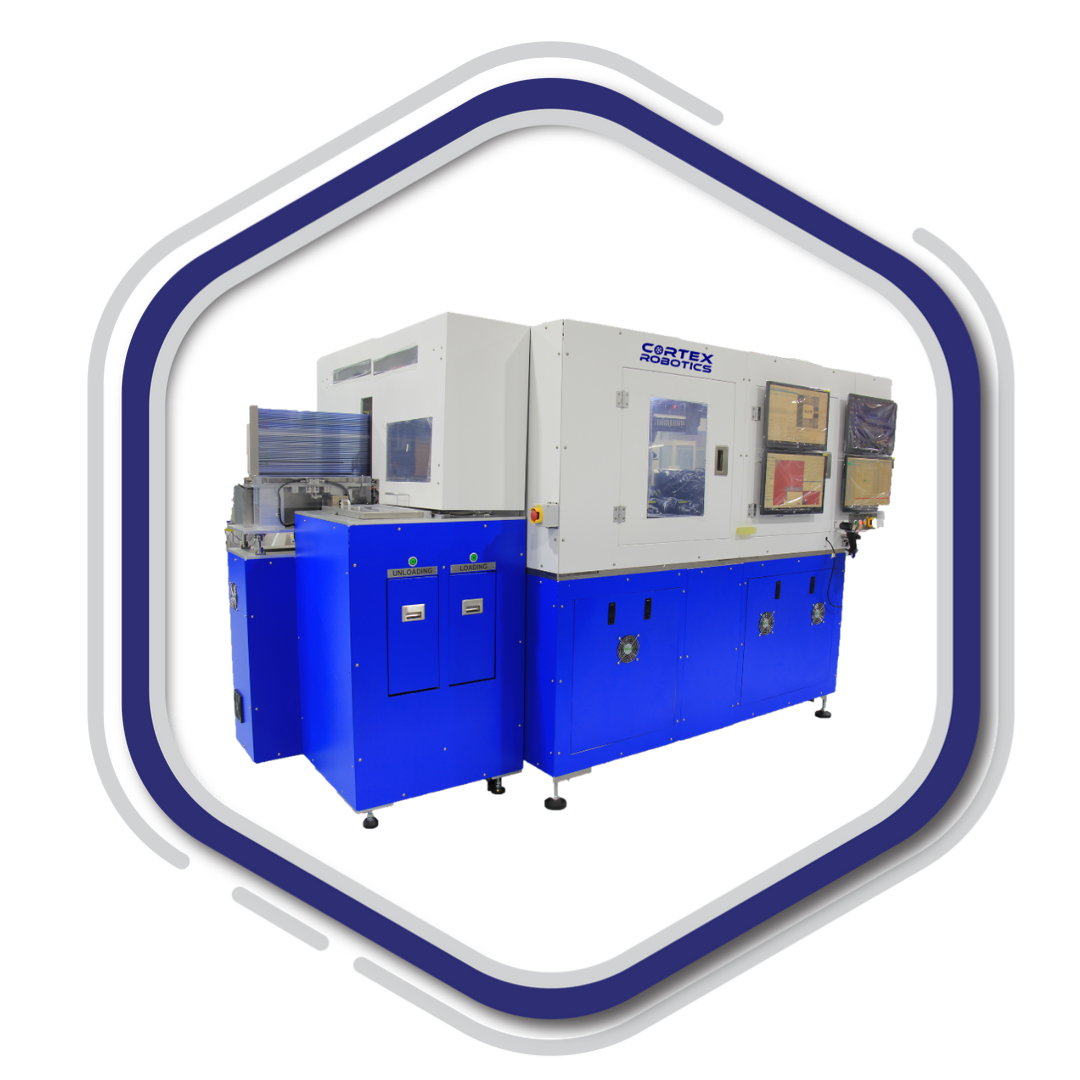

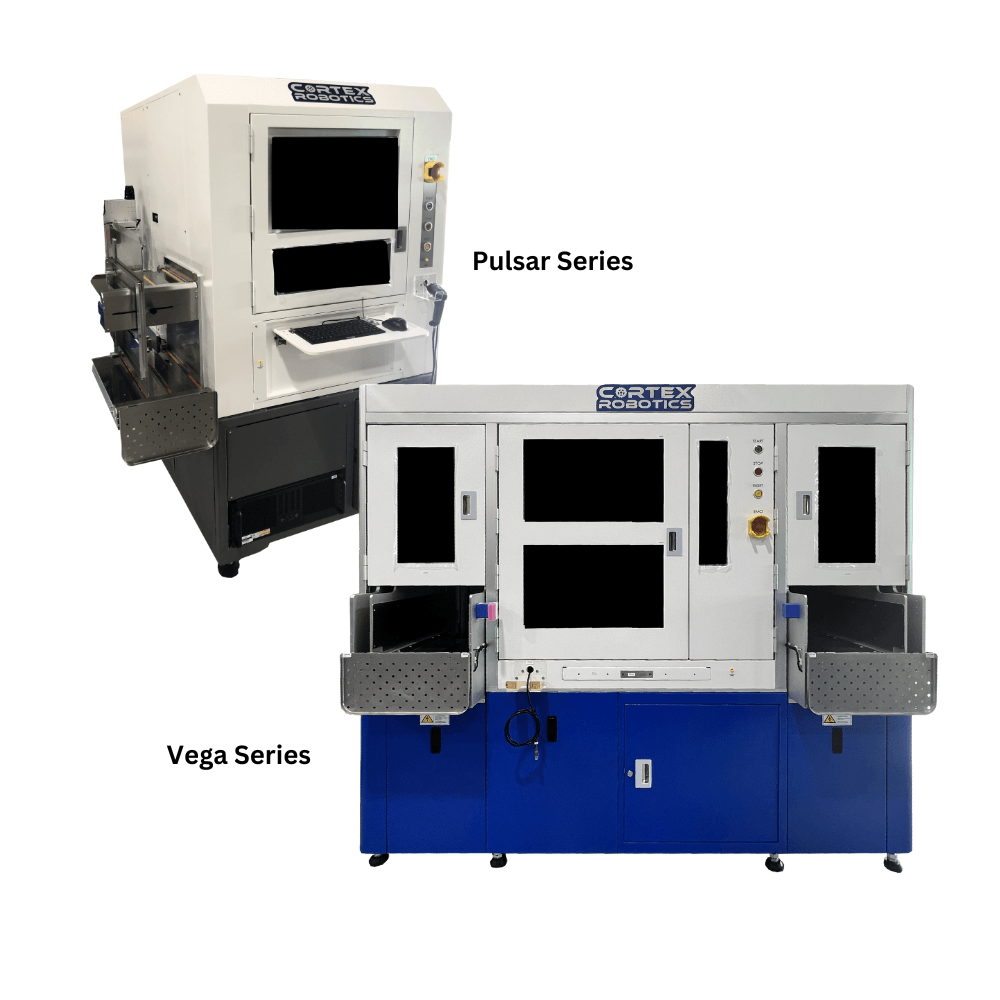

VEGA SERIES

Precision 3D Wirebond and Die Bond AOI Solution

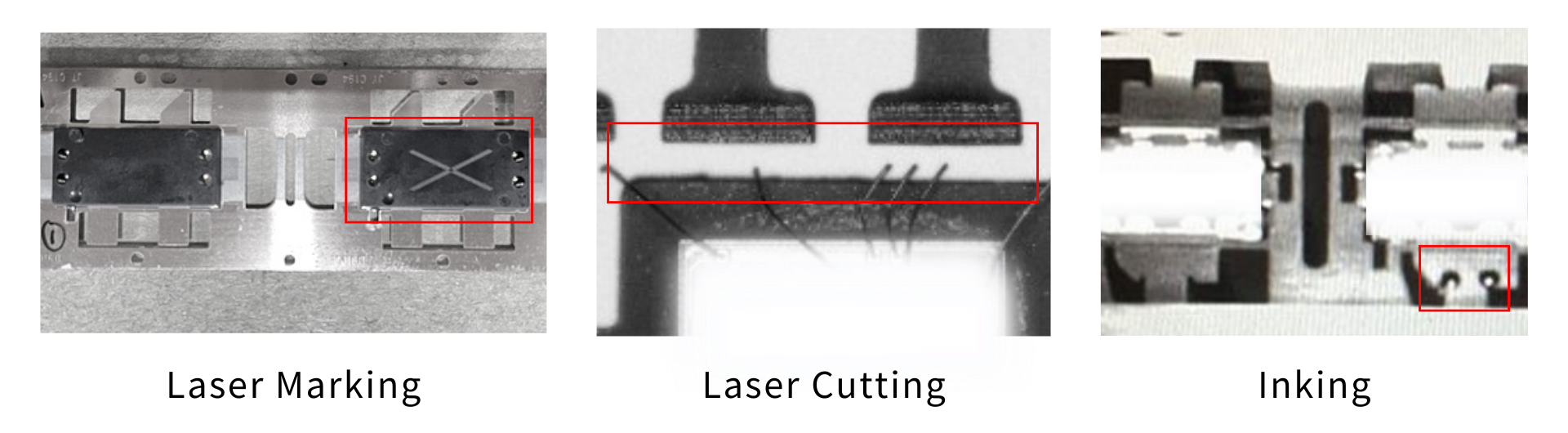

Vega is a High Precision Wire bond Inspection (AOI) solution equipped with the latest & high-specification 3D technologies which able to perform a smarter and high accuracy height measurement inspection on the die and on wirebond. It’s designed to support inspection before and after the wire-bonding process. It has the capability to inspect the top and bottom of the many types of products (Leadframe, Substrate & Pallet, Grip ring, wafflepack, gelpack, JDEC tray) with only a few steps of recipe change. The 3D Wire Bond Inspection has the ability to detect not only the common wire bond defect but also defects such as wire drop, die tilt, and more. It comes with a multi-choice of reject modules that suit your need, for example, laser marking, laser cutting, inking, and Pick&Place.

Vega Series-Fully automation with dual loadport for Flexible input & Output with minimal recipe adjustments.

Pulsar Series – Compact in size, allowing easy integration into inline production and optimizing factory space.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

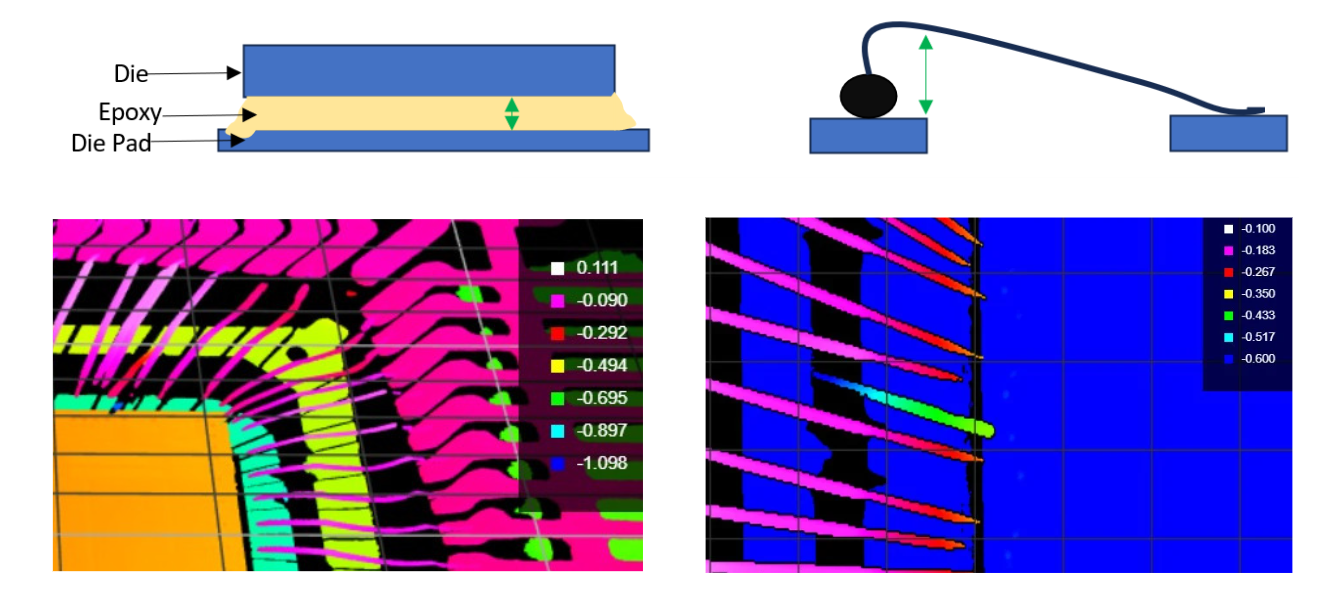

3D Inspection for BLT & Loop Height

Multi-Choice Reject Modules

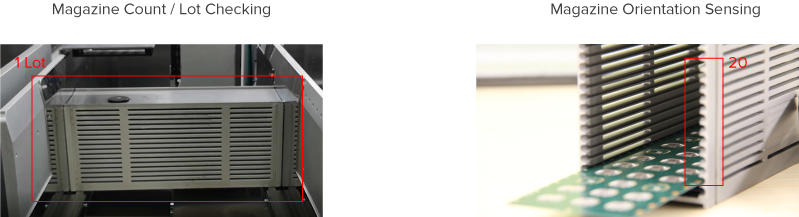

Multiple Magazine Conveyor

1D / 2D / RFID Magazine Reader

Other Features

8 to 1 Centralised Verification System

Centralised Recipe for Handler & Vision

Stacked Die Out of Focus Handling

Wire Tracing Technology (Full Wire Coverage)

Automatic Defects Classifier Host Support

Auto Focus (Warp Compensation)

Smart Recipe - Auto Search Ball/Weld & Wire Path

SECSGEM Compatible

Optional Features

Offline Teaching

Bottom Multi-view Inspection

Long Term Storage (Up to 3 Months)

Offline Verification Before Reject

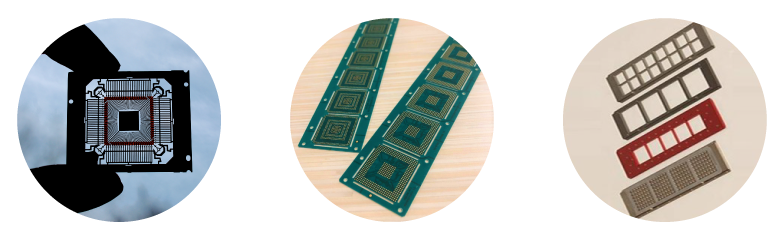

INSPECTION PRODUCTS

Substrate, Leadframe and Pallet

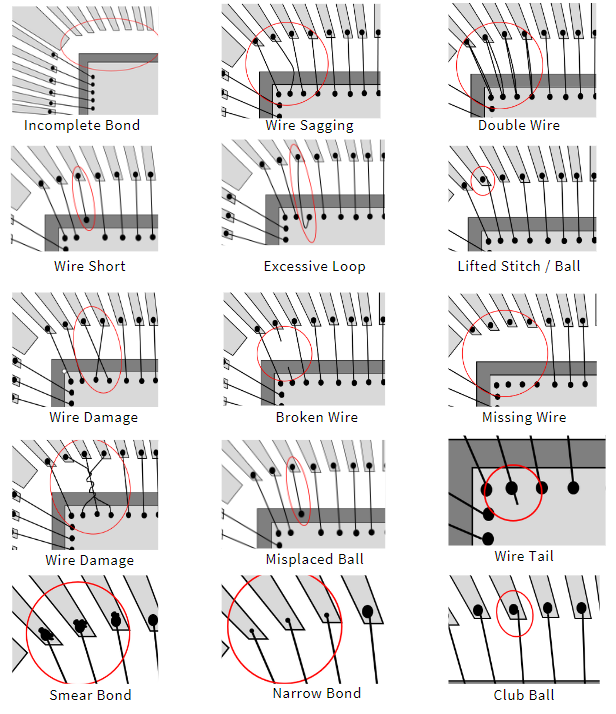

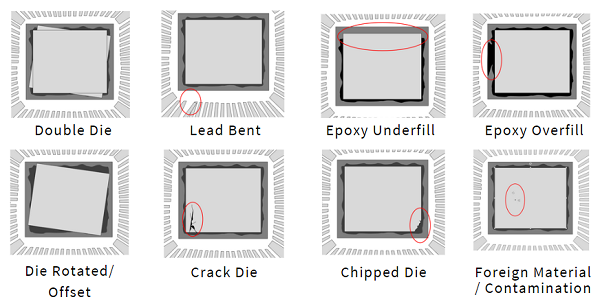

INSPECTION CAPABILITIES

Wire short, wire broken, wire sagging, wire sweeping, torn bond, wire missing, double-bond, lifted wire, lifted ball, ball dimension, particle on die, die off set, epoxy overflow, lead bent, lifted stitch, cross wire, J wire, wire neck, wire heel and golf/club ball