Description

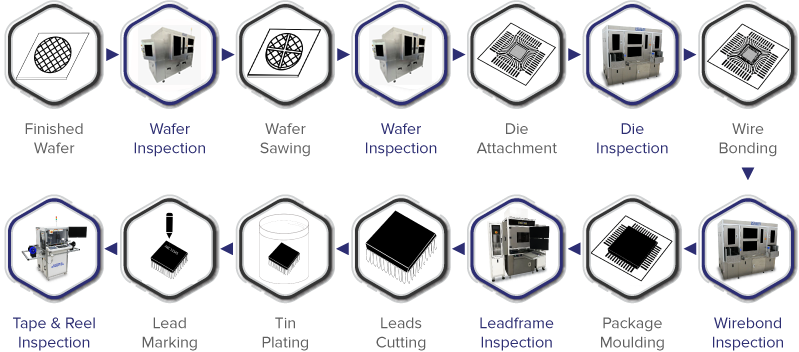

Our AOI Solutions Supported the Backend of Semiconductor Manufacturing Process

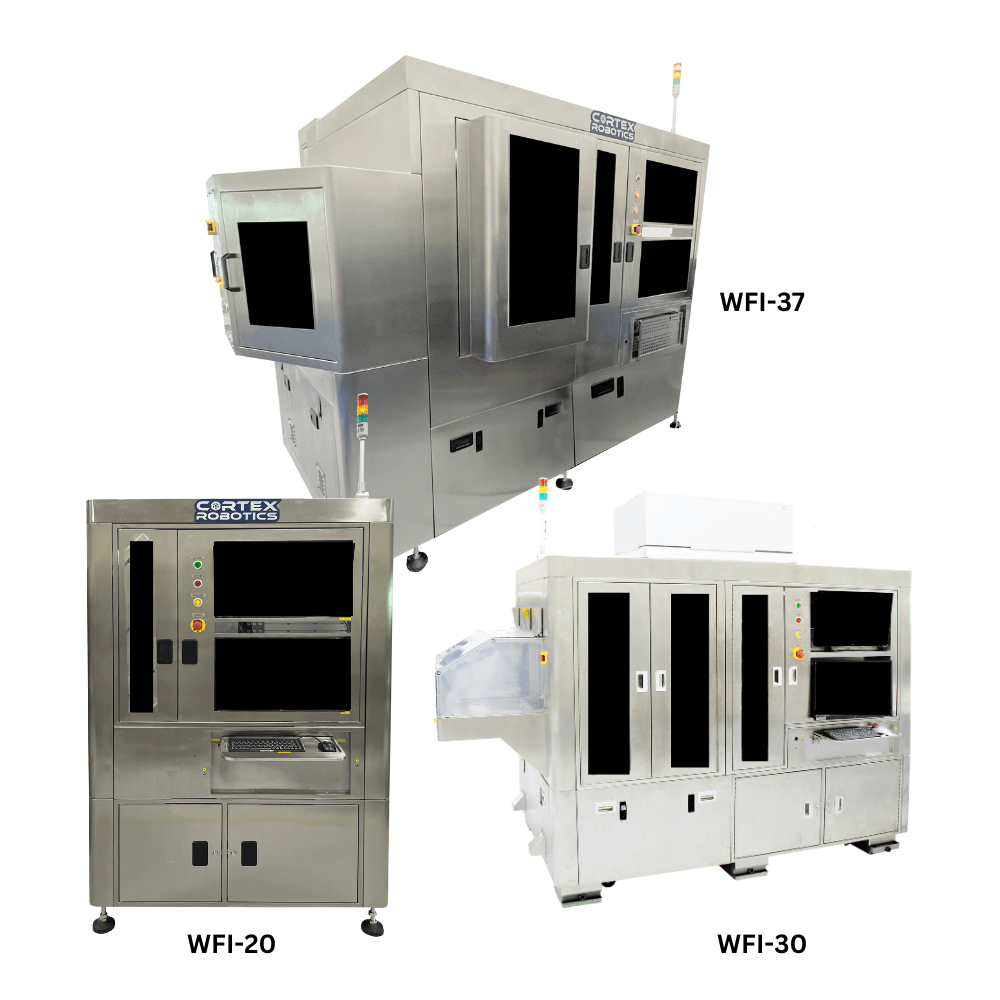

ALPHA SERIES

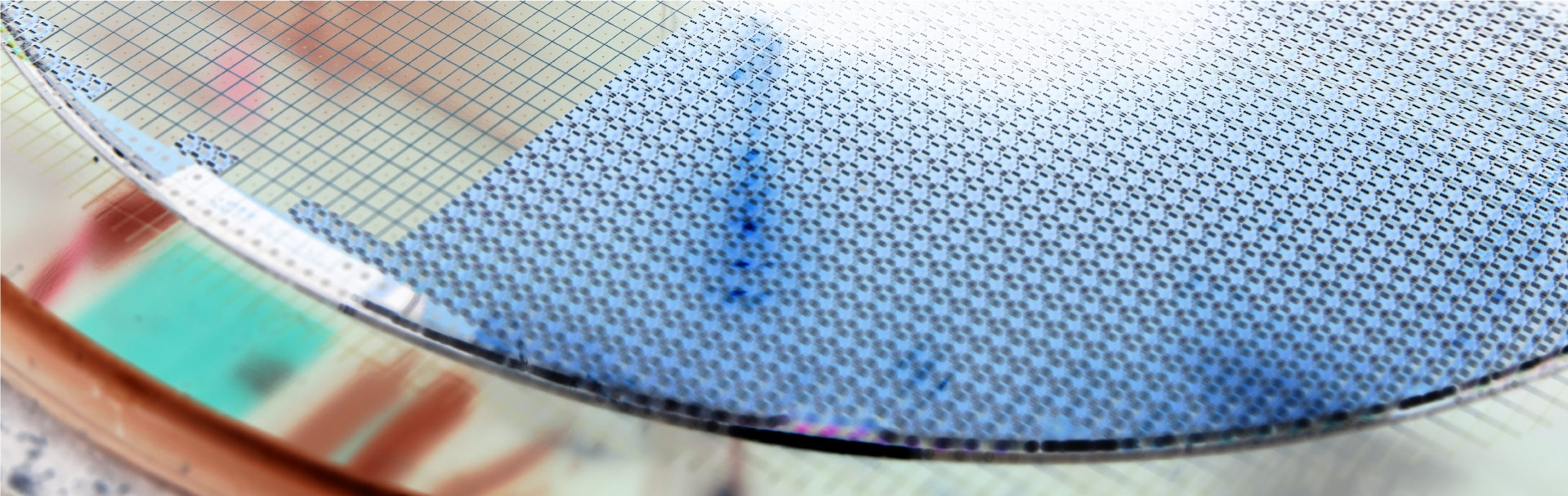

High-Performance 2D + 3D/ SWIR Wafer AOI Solutions

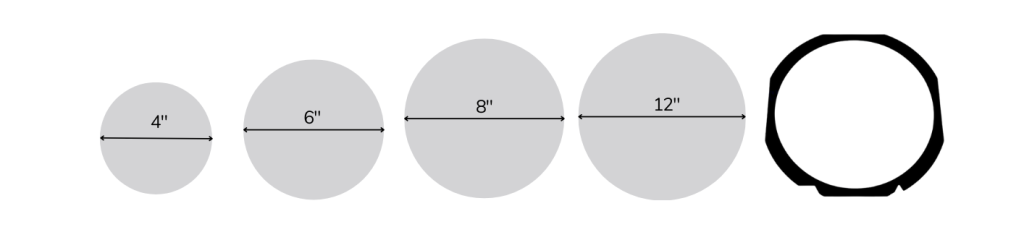

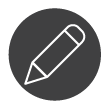

The Alpha series stands as a leading solution in semiconductor defect inspection, expertly designed by Cortex. Our high-performance Wafer Automated Optical Inspection (AOI) systems deliver precise and reliable detection of both major and minor wafer defects, making them ideal for inspections before and after the sawing process. This versatile solution accommodates a wide range of wafer types and sizes across various industries, including semiconductor, electronics, automotive, medical, and optoelectronics.

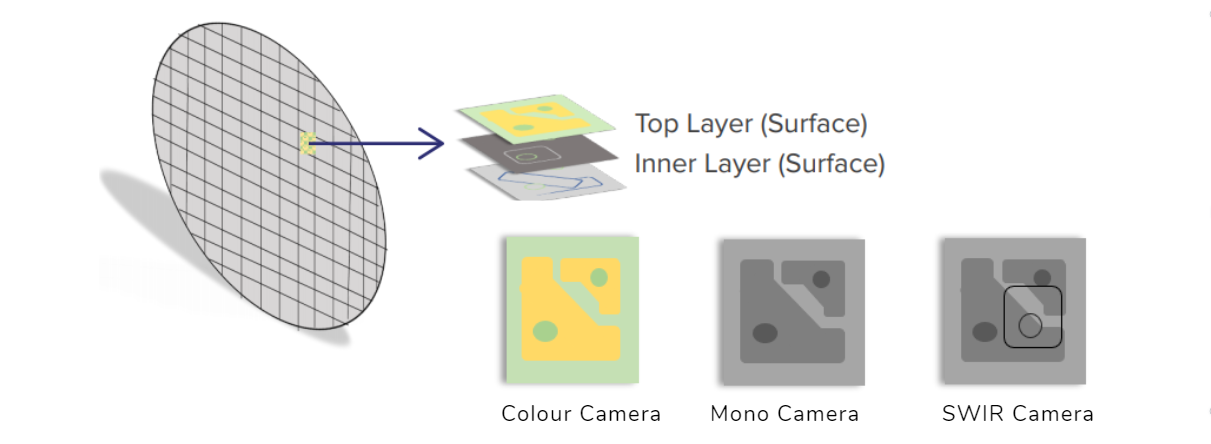

The upgraded Alpha series now incorporates SWIR (Short-Wave Infrared) technology, enhancing its capability to inspect die inner layers and sidewall defects. This advanced SWIR wafer inspection solution is outfitted with state-of-the-art hardware and software, significantly accelerating wafer transition and inspection processes.

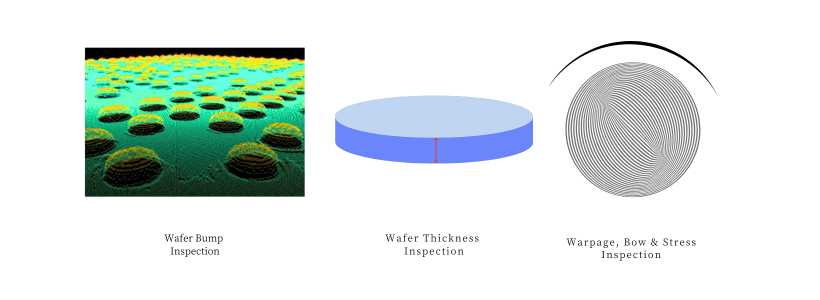

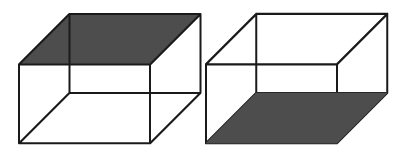

Furthermore, the latest iteration of our wafer AOI series features substantial advancements in 3D technology, enabling precise measurements of wafer bumps, warp, bow, total thickness variation (TTV), and thickness for silicon wafers, as well as for matted and polished glass wafers. This makes it particularly well-suited for advanced packaging applications.

WFI-20 -A compact, versatile AOI system designed for seamless integration with various loadports, ensuring inline compatibility for streamlined inspection.

WFI-30-Equipped with dual loadports and a robotic arm, enhancing throughput and automation for high-volume production environments.

WFI-37-Advanced top-and-bottom inspection capabilities with dual loadports and dual robotic arms, providing comprehensive defect detection with maximum efficiency.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

Other Features

Defect Detection 0.5um

Fine Die Inspection 300um x 300um

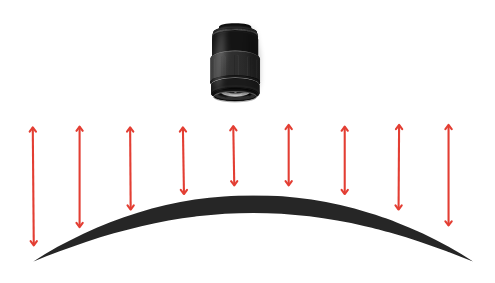

Auto Focus (Warp Compensation)

Host Map Format Adaptability [Klarf, XML, and etc)

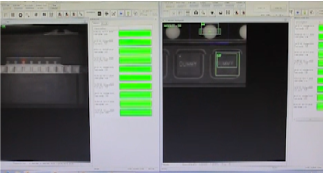

Live Result Display

Auto Mapping

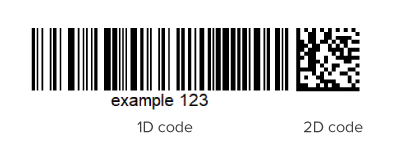

2D Code Reader

Ionizer & Hepa Filter

SECSGEM Compatible

Optional Features

Reject Modules

Offline Verification Software

Bottom Inspection

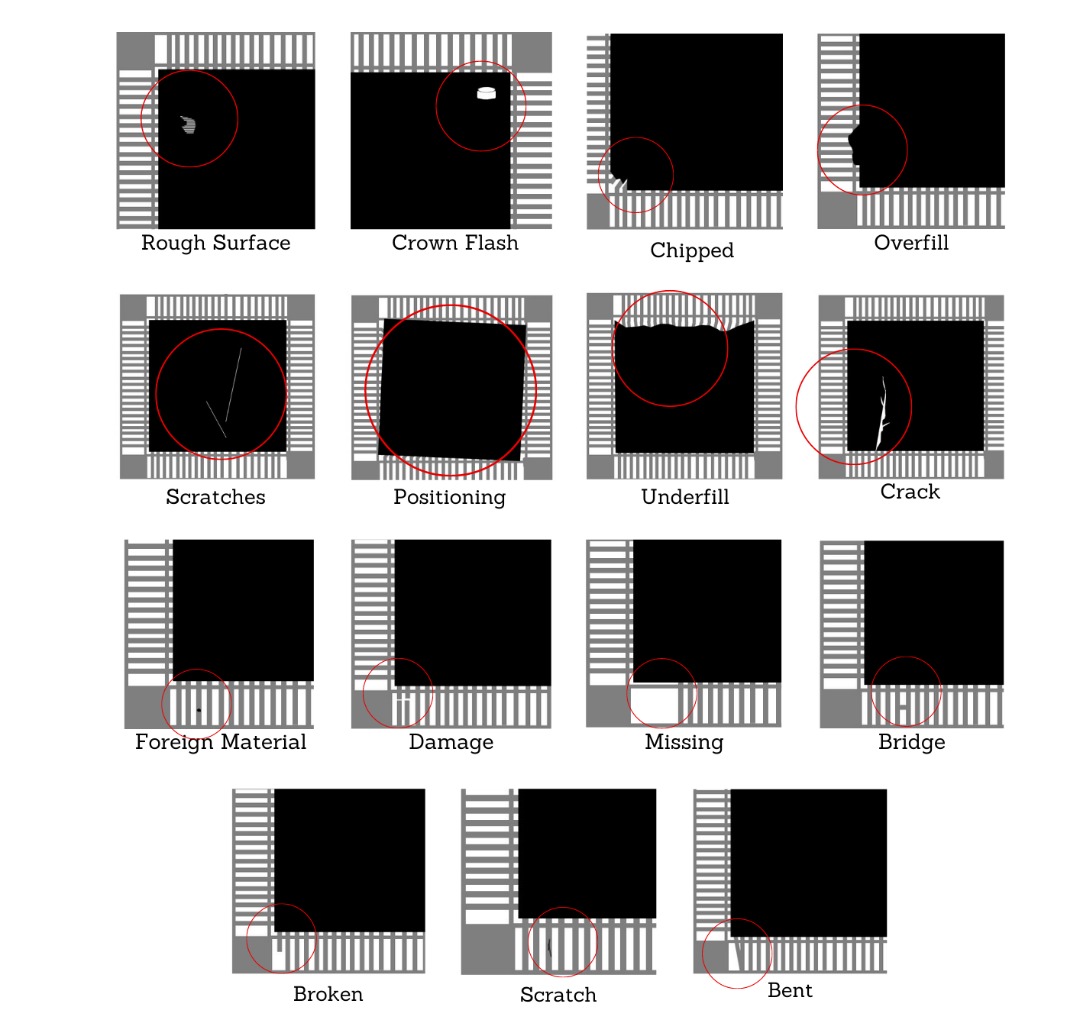

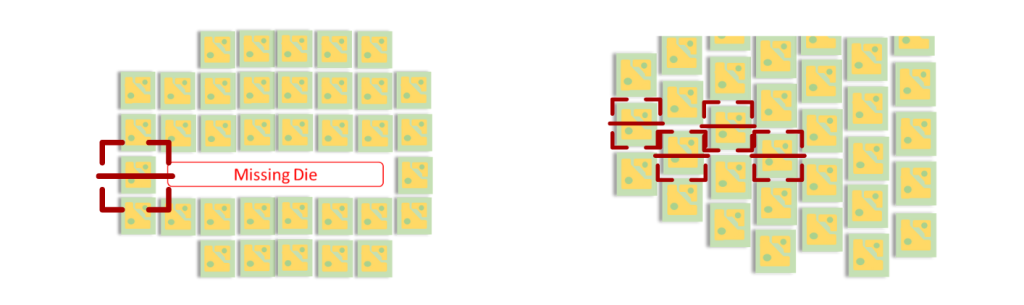

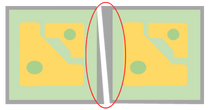

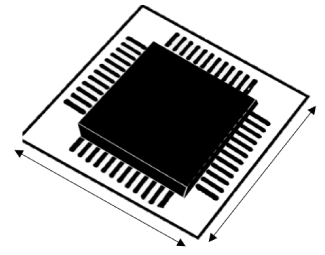

INSPECTION CAPABILITIES

Chipping, Cracks, Stains, Blistering, Scratches, lifted metal, meandering, damaged bump, un-separation, 0ff set –cut, foreign material, slant cut, discolor, measurement, OCR and etc

*In order to protect our customer design, drawing act as illustration purpose only. Contact us for more information

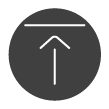

ELECTRA SERIES

Tape & Reel AOI Solutions

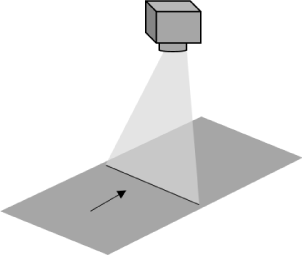

Electra is a powerful High-Speed Tape and Reel AOI Solutions that is capable to inspect fine defects.

Its support various pocket width of tape and reel.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

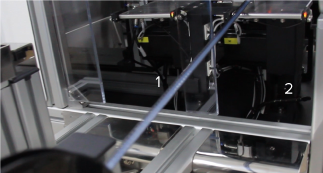

Dual Track Operation

Autosave failed defect images

Fine detection to 4 mils defects

Line Scan 8K, 12K, 16K Camera Capabilities

Other Features

Single software with multiple inspection recipe

Network connectivity for output to server

Defect mapping with images

Optional Features

Laser marking system

Offline Programming

2D code reading

NAS Storage Solution

INSPECTION PRODUCTS

Tape & Reel

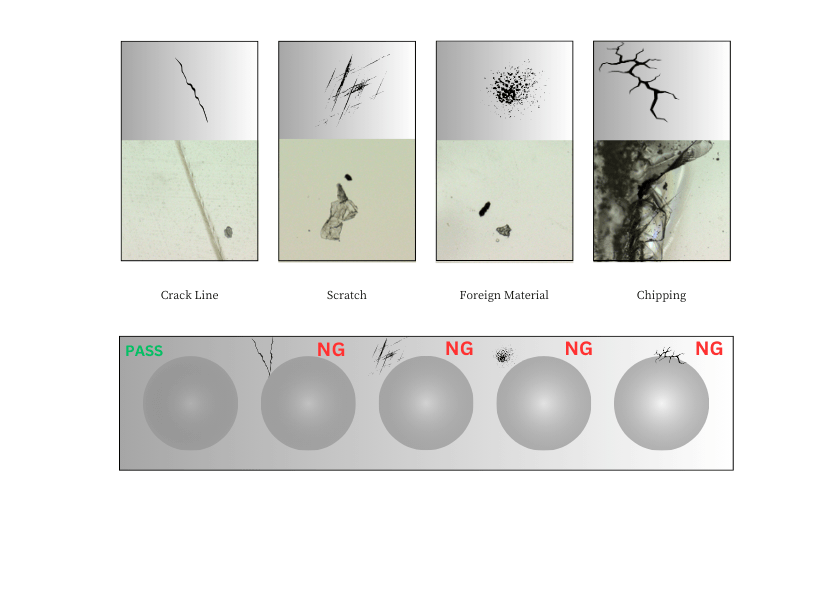

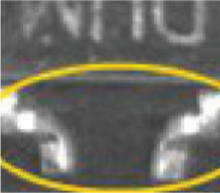

INSPECTION CAPABILITIES

Scratches, chipping, wrong marking, wrong orientation, foreign material and lead bend

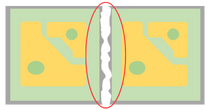

Scratch

Chip Out

Wrong Marking

Wrong Orientation

Foreign Material

Lead Bend

VEGA SERIES

High Precision 3D Wirebond AOI Solution

Vega is a High Precision Wire bond Inspection (AOI) solution equipped with the latest & high-specification 3D technologies which able to perform a smarter and high accuracy height measurement inspection on the die and on wirebond. It’s designed to support inspection before and after the wire-bonding process. It has the capability to inspect the top and bottom of the 3 types of products (Leadframe, Substrate & Pallet) with only a few steps of recipe change. The 3D Wire Bond Inspection has the ability to detect not only the common wire bond defect but also defects such as wire drop, die tilt, and more. It comes with a multi-choice of reject modules that suit your need, for example, laser marking, laser cutting, inking, and Pick&Place.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

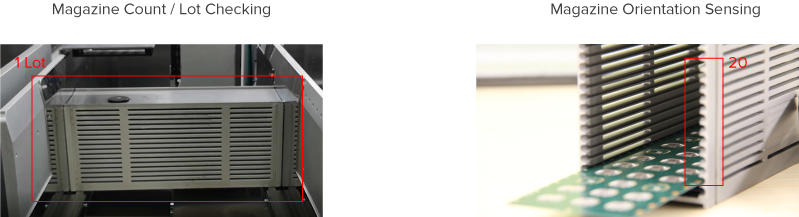

Key Features

Multiple Magazine Conveyor

1D / 2D / RFID Magazine Reader

Other Features

Quality Analysis System

Generate Report

E-Map

High-Resolution Camera & Auto focusing

8 to 1 Centralised Verification System

SECSGEM Compatible

Auto frame width Adjustment

Able to perform offline verification before reject

Optional Features

Reject Modules (inking, sorter & laser marking)

Bottom inspection

Long Term Storage (up to 3 months)

Offline Teaching

INSPECTION PRODUCTS

Substrate, Leadframe and Pallet

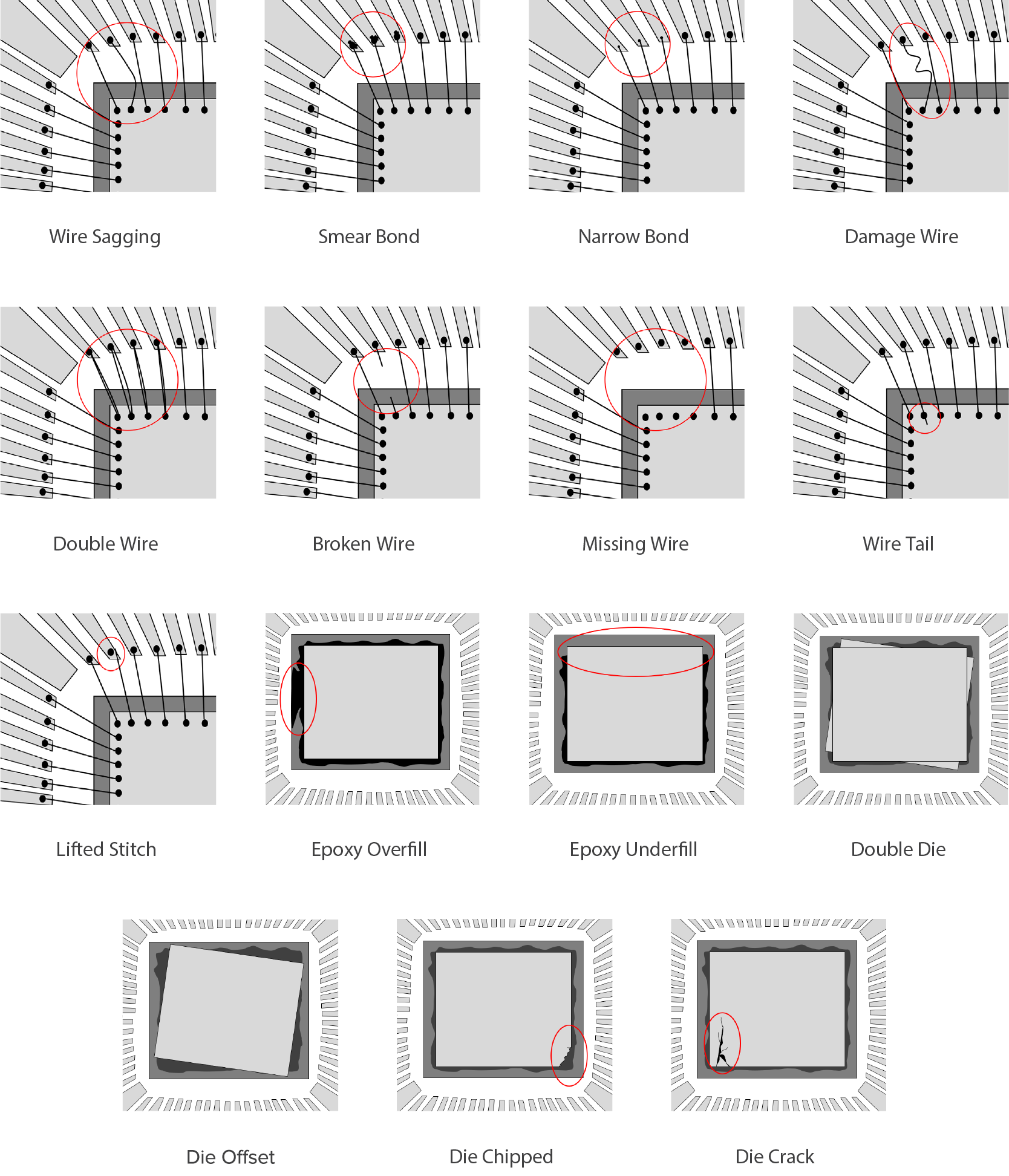

INSPECTION CAPABILITIES

Wire short, wire broken, wire sagging, wire sweeping, torn bond, wire missing, double-bond, lifted wire, lifted ball, ball dimension, particle on die, die off set, epoxy overflow, lead bent, lifted stitch

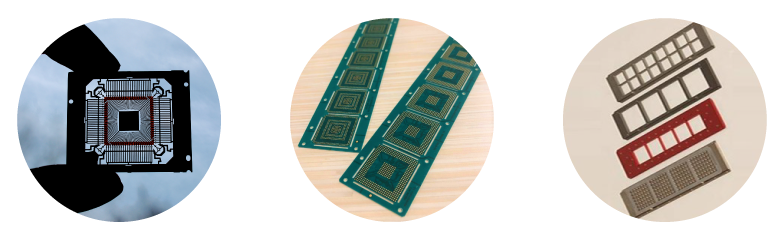

MIRA SERIES

Strip to Strip AOI Solutions

Mira is a High-Speed Strip to Strip AOI solution with multiple inspection capabilities and low energy consumption solutions.

Its also able to do inspection on die attached and various types of leadframe and package.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects

process

Improve Reputation

Less defects products

increase customer

satisfaction

Low Energy Consumption

For greener earth

Reduce Wastage

Defects can be detect

at the earlier stage

Save Time & Cost

Process can be simplify and

less labour cost

24 hours operation

Maximize production yield

RoHS Compliance

Component

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

Dual Scan Capabilities Top & Bottom Inspection

1D & 2D Reading

Fine detection to 2 mils defects

Line Scan 8K, 12K, 16K Camera Capabilities

Other Features

Single software with multiple inspection recipe

Network connectivity for output to server

Defect mapping with images

Optional Features

Laser marking system

Able to perform offline verification without disturbing the on-going process

NAS Storage Solution

INSPECTION PRODUCTS

Package, Leadframe, Die Attach

INSPECTION CAPABILITIES

Mark & Cosmetics inspection – Rough surface, void, package scratches, incomplete fill, crown flash (2D), ID Pin Height, Chip on package, raised flag, package offset, foreign material, pin1 chip, flash on EP and etc