Description

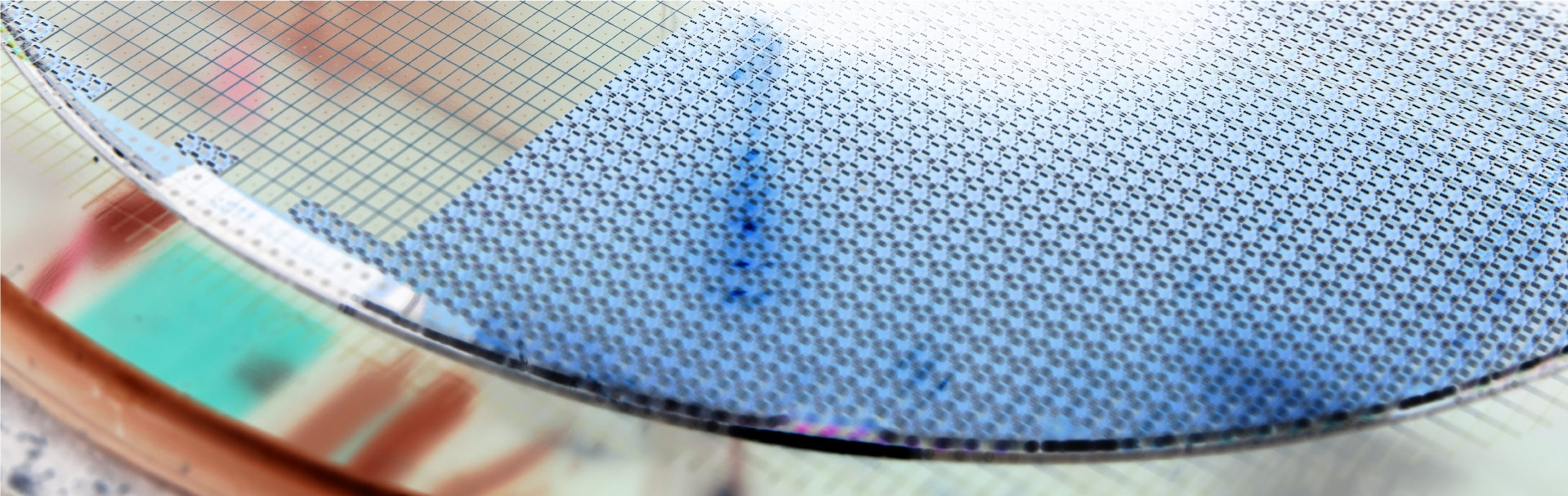

Our AOI Solutions Supported the Backend of Semiconductor Manufacturing Process

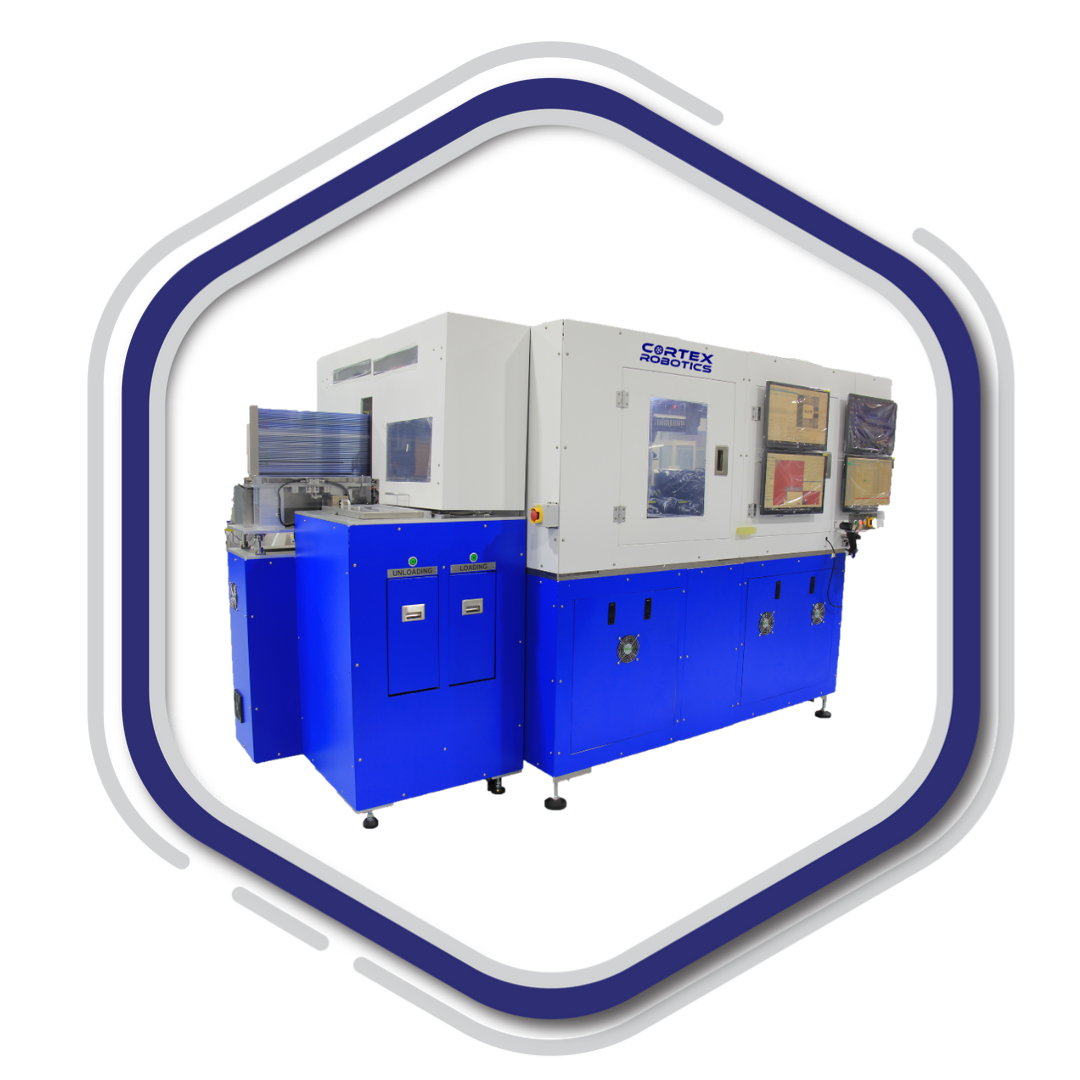

Meteor Series

Turret AOI

Meteor is a 10 Sided High-Speed On-The-Fly Automatic Optical Inspection machine. This machine adopted some new approaches & methods in inspection to cover all the inspection surfaces and widest defect list while providing the highest output yield. IC inspection before packaging process.

Supporting many types of industries including semiconductor and Optoelectronics Industry.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Features

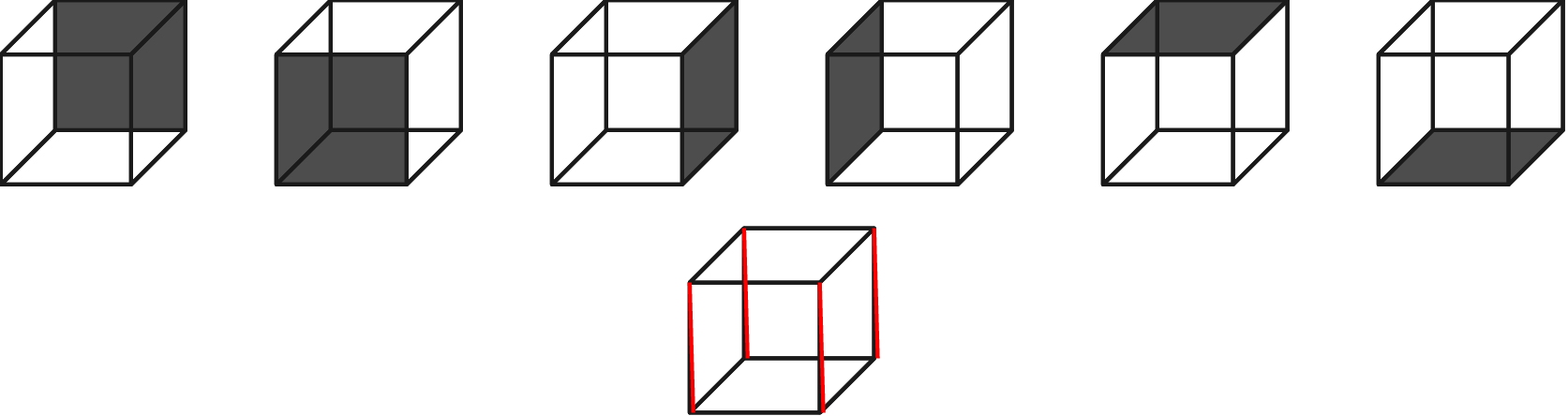

10 Sided Inspection Coverage

6 sides included 4 corner of the inspection objects

Wide Product Size Support

7.24mm x 6.48mm

19.56mm x 32.33mm

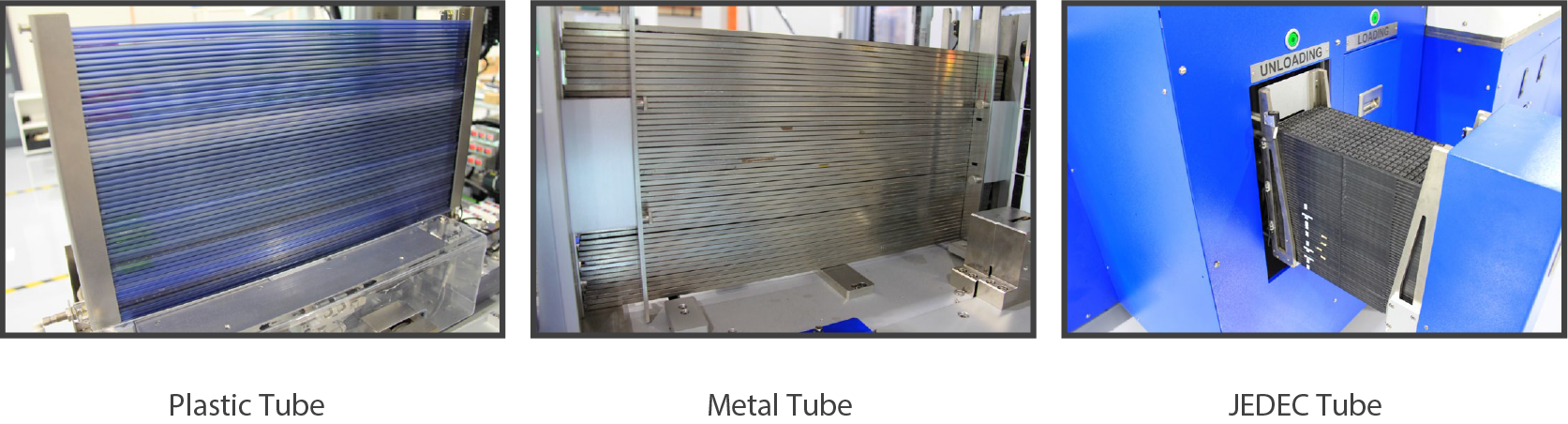

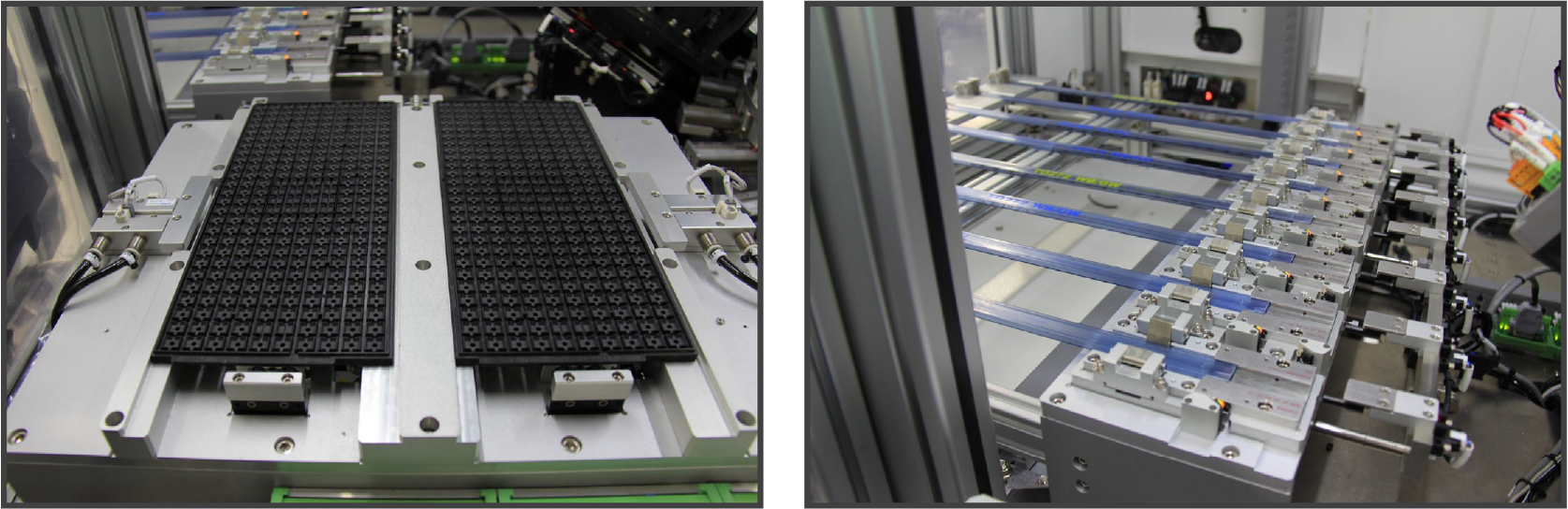

Flexible Input & Output

Tube to Tray | Tray to Tray | Tray to Tube |Tube to Tube

Reject Station

Defects products will sort into the tube or tray

Other Features

Motorized Camera Focusing (Auto-Focus)

Generate Report & Save Image

Reject Object Mapping

SECSGEM

Optional Features

Marking

Offline Teaching

Long Term Storage (up to 3 months)

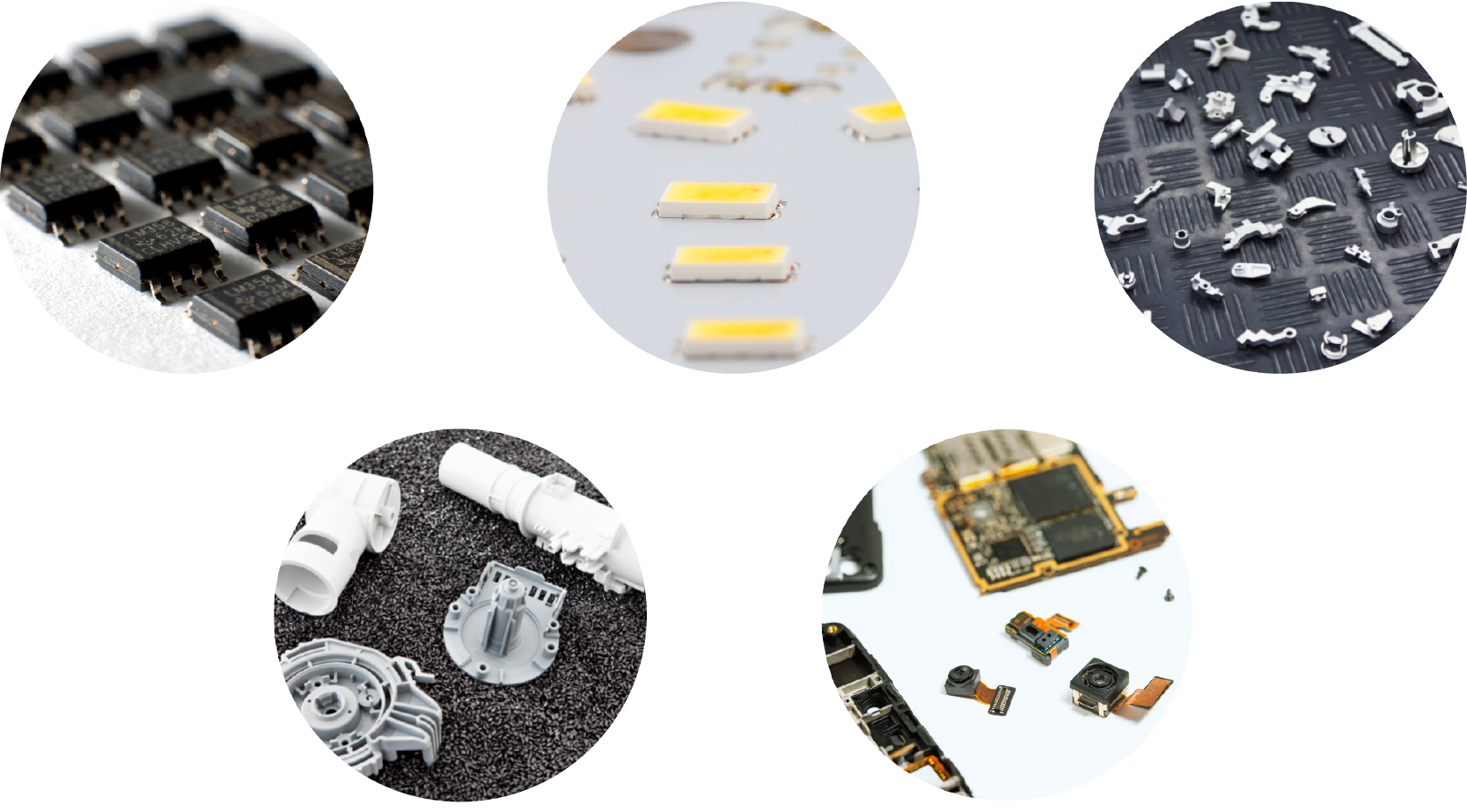

INSPECTION PRODUCTS

IC Chips and many range of singular Products in Semiconductors industry, plastics parts in plastic injection molding & smart devices Industry, metal parts from automotive or precision metal fabrication Industry

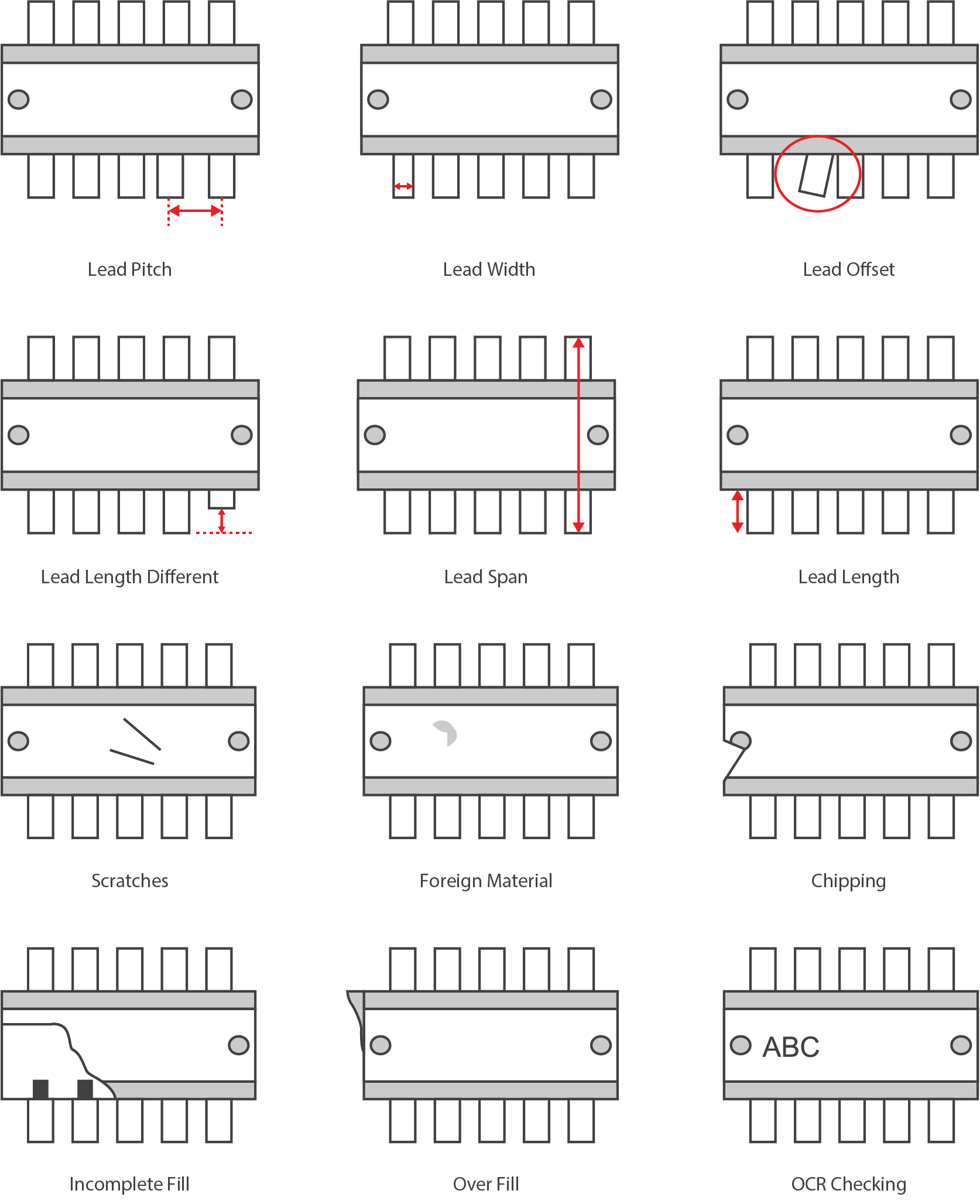

INSPECTION CAPABILITIES