BLOG

5 Reasons Why You Need Automated Optical Inspection Machine (AOI)

AOI machines are designed to evaluate thousands of details on printed circuit boards (PCBs) that the human eye cannot catch. The machine also reports the defects (if any) to the operator.

As part of the different methods of inspection that manufacturers should use, the AOI system handles the majority of inspection on PCBs.

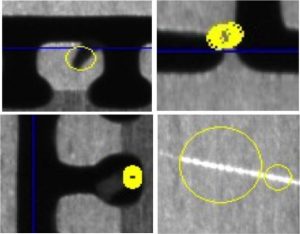

The AOI equipment solution uses a system of high-resolution cameras along with different sources of illumination like fluorescent, LED, ultraviolet, and infrared, to capture many images.

The images are processed by the system pre-programmed to examine various details of the assembled board.

Attributes of the AOI Machine

- High definition cameras and high-end lighting systems.

- The images captured are clear and of a high quality due to its effective lighting system.

- They are designed with an inbuilt software that processes a comparison of required parameters with that of the captured image. With this, it is easy to find the tiniest errors in the PCB.

- It uses different algorithms such as pixel counting and inspection to view and analyze the image from different angles. Other algorithms include blob analysis, template matching, object recognition, and vectorial imaging technology.

The vectorial imaging technology is used for PCB and assembly inspection. It is a pattern search technology based on geometric figure extraction.

So, here are five reasons why you need AOI in your facility as part of your inspection tool.

The Need For Automatic Optical Inspection (AOI)

1. Speed of Inspection

The AOI machine is quick. Visually inspecting the printed circuit board may take hours, and you could end up missing certain defects. After the initial programming, the AOI system can take a minute to run through an entire panel of circuit boards.

It keeps the products moving faster throughout the manufacturing facility than if the boards were waiting for a visual inspection.

2. Helps to detect visual defects on PCBs

Even with the speed of inspection, the AOI machine is designed with high-resolution cameras and different sources of lighting that accurately check errors on the board, including stains, missing or wrongly mounted components, and scratches. The human eyes can easily miss these defects because most of them are almost invisible to the eye.

3. Inspection Consistency

With visual inspections, consistency can be far-fetched. The expert inspectors may have a great, quick process for each board they inspect, but as good as they are, there will be errors in that method.

With an AOI machine, the images are in the same position as every single panel that goes through the machine. The camera does not miss inspecting a part by accident, and it could catch some things that an inspector may miss (since it doesn’t get tired). The machine gives an accurate and consistent output every single time.

4. Cost-Effectiveness and Flexibility

When compared to other methods of inspection, such as X-ray, AOI is cost-effective. In the long run, AOI is profitable for PCB manufacturers since it prevents flaws in production and increases production value.

Also, the AOI system is flexible since it can be used during any stage of the production process. Also, it can be applied as many times as needed.

5. Less Strain and Quick Catches

Finally, the AOI machine takes away a lot of strain — not just on the human inspectors, but the entire process as well. The quick catches during the SMT process help to prevent rework, thereby moving the product efficiently, throughout the facility.

It is important to note that AOI systems can be ineffective if not programmed correctly. You need competent handlers to program the machine the right way if it must run at 100 percent efficiency. There are good qualified AOI equipment providers in Malaysia, such as Cortex Robotics that can help program the machine to run effectively. For more information, feel free to contact us on our website.

Contact Us

Cortex Robotics Sdn Bhd.

address

72-2-6, Arena Curve, Jalan Mahsuri,

11950 Bayan Lepas, Penang, Malaysia.

T: +604 – 611 0110

E: info@inspiren.dev

social media

quick link