BLOG

What Is A Lead Frame Inspection

What is a lead frame?

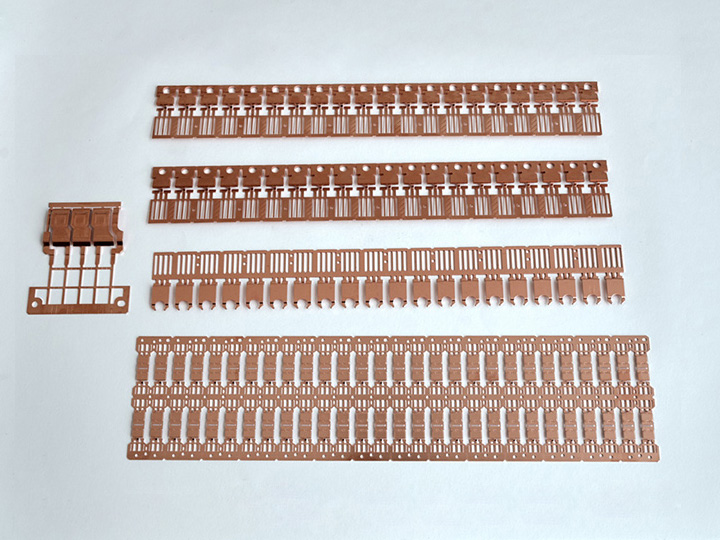

A lead frame is a thin layer of metal that is utilized in the semiconductor device assembly process. It is used to connect the large-scale circuitry on circuit boards and electrical devices to the tiny electrical terminals etched on the surface of the semiconductors. Almost every semiconductor package utilizes a lead frame.

Thus, lead frames are used to create most kinds of integrated circuit packaging. Basically, the silicon chip is placed on the lead frame and then metal leads of the lead frame are bonded to the chip. Finally, the connection is covered with plastic.

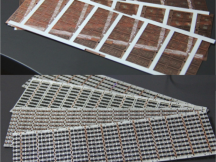

Lead frames are manufactured on assembly machines and shaped into long strips. However, there is no ‘one size fits all’ measurement applicable in the production process.

Often, the production of lead frames is customized according to the specifications, features, thermal properties, and electrical properties required by the client.

Lead frames are created using two procedures – Photo etching and Stamping.

What is lead frame inspection and why it is necessary?

Lead frame inspection is the process of inspecting lead frames. In the manufacturing industry, it is necessary to detect any defects present in the manufactured products to ensure product quality and continuously improve the production process to produce better quality products. Lead frame inspection is done due to the same reason.

Detecting faulty lead frames early on during the manufacturing process by conducting lead frame inspection is extremely important. It prevents manufacturers from wasting time, money, and other resources. Plus, it also allows them to detect problems with the production process.

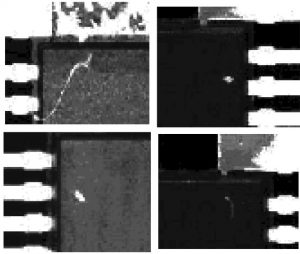

Even a single defect in a lead frame due to poor plating quality or contamination can result in complete failure of the whole integrated circuit and cost the company a lot of money.

How is lead frame inspection done?

Previously, lead frame inspection was done manually by human inspectors. Nowadays, lead inspection is conducted using automated optical inspection machines (AOI). An AOI machine visually scans the surface of the lead frame to detect any surface feature defects such as scratches, nodules, stains.

AOI machines can also detect dimensional defects such as shorts, open circuits, and thinning of solder as well as missing components, incorrect components, and incorrectly placed components.

A high-quality image is first captured by the AOI machine by using high definition cameras and shining bright lights on the lead frame surface. The image captured is then processed by it and finally compared with the information stored the machine that allows it to determine how a defect-free lead frame should look like.

An AOI machine can use template matching, pattern matching, or statistical pattern matching to analyze whether a lead surface has any defect.

Why is it necessary to use an Automated Optical Inspection tool for inspecting lead frames?

Modern integrated circuits and lead frames have experienced dramatic improvements in recent years. These are now far more complex than just a few years ago, smaller in size, and contain numerous soldered joints.

Thus, it is not possible to manually inspect modern lead frames in an accurate manner. Not to mention that it is also a very slow process. AOI machines can automatically inspect modern lead frames much faster and more reliably than human workers. Thus, AOI machines are indispensable for lead inspection and also cheaper in the long run.

It is very important to get a good quality AOI machine from a trusted AOI equipment provider. AOI machines sold by different AOI equipment providers are not the same.

They can vary greatly in their features, cost, and quality. So, it is important to choose an AOI equipment provider who has a good reputation in the industry. For more information, contact our professional sales consultants.

Contact Us

Cortex Robotics Sdn Bhd.

address

72-2-6, Arena Curve, Jalan Mahsuri,

11950 Bayan Lepas, Penang, Malaysia.

T: +604 – 611 0110

E: info@inspiren.dev

social media

quick link