BLOG

What is an Automated Optical Inspection Machine (AOI)

The automated optical inspection machine (AOI machine) is a machine that is designed to perform vision inspection automatically. The versatile machine can practically work on any devices that need precise vision inspection.

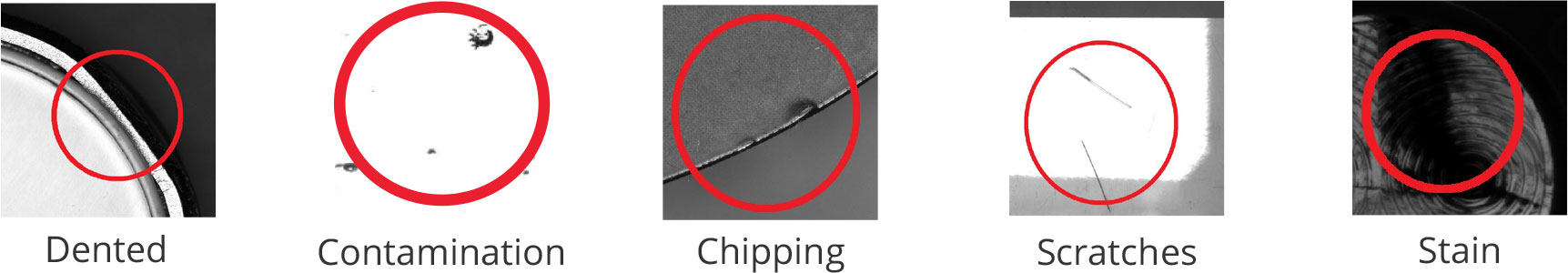

It is used to guarantee that the standard of products leaving the line of production is top-notch – without any manufacturing or assembly deficiencies.

The Need For Automatic Optical Inspection (AOI)

In spite of the significant advancements in technology, present-day circuits are unquestionably more complex than boards were some years ago. Hence, the need for AOI solutions.

The ensuing decrease in size and the introduction of surface mount technology implies that boards are notably compact. Even moderate boards have a significant number of soldered joints, and this is where most of the issues develop.

The increase in the complication of boards also implies that manual inspection is not a feasible choice these days. Although the manual inspection approach is accepted, it is not very effective.

The reason is that inspectors get tired often; therefore, incorrect construction may go unnoticed. Therefore, it requires an automated inspection; to make the task faster and more efficient – without so much effort on the part of the operator.

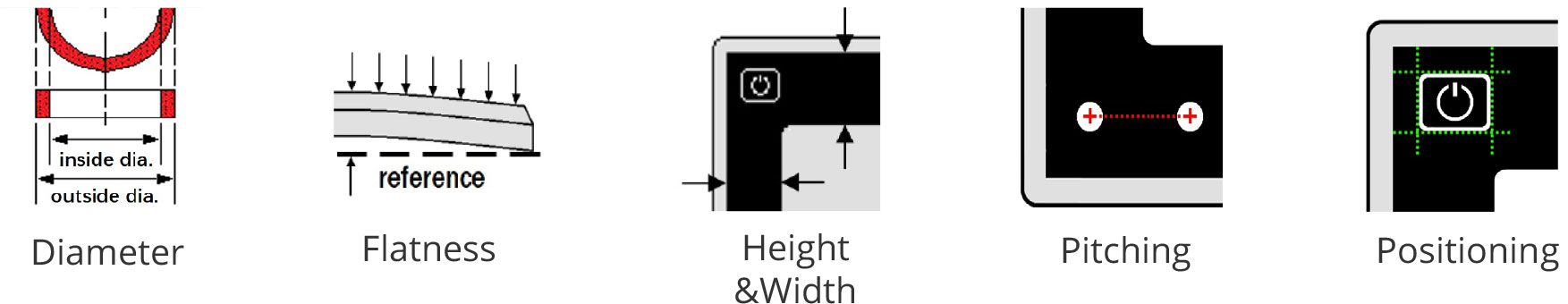

The automated optical inspection machine also used as an integrated electronics test strategy to guarantee cost-efficiency. It helps in the early detection of faults in the line of production as the marketplace requires a high volume of top-quality products to be brought into the market very reliable and quick.

It implies that a fast and reliable method is needed to check and ensure that the quality of the products is 100%.

The automated optical inspection machine is simply the solution. The AOI machine can be introduced into the line of production immediately after the soldering process.

With this, problems can be noticed early in the production process. The automated optical inspection machine is very advantageous, as it ensures that process problems in the soldering and assembly area are detected early.

Critical Uses/Advantages of automated optical inspection machines

There are three main advantages of AOI machines;

- To identify errors in the line of production, and quickly send feedback to avoid a repeat of the failure.

- To contain high-speed effectiveness with time to enable that corrective measures are taken timely.

- To be fast (easy programming and operation) to enable an inspection to be completed with a reliable result and promptly.

Automated optical inspection machine programming

Details for an acceptable board must be stored (programmed) on the AOI machine to be able to test a PCB assembly.

Also, the programming must be done correctly to enable the automated optical inspection machine to detect any fault or error.

Below are two methods that can be used to program an AOI machine:

- Use of “Golden Board”: In this method, a known good board is used as a target for the AOI machine. This board is passed through the machine so that it can review the crucial attributes.It looks at the components and takes into consideration the solder profiles of each joint and many other aspects.

- Algorithm-based programming: In this method, PCB data is provided to the AOI machine for it to generate its profile for the board.This method requires real boards also, but few are needed compared to the golden board method.

In a Nutshell

It is essential to check the quality of boards coming off the end of a production line. With this, the quality of the boards can be monitored, and faults are detected and fixed early to prevent a recurrence.

It, therefore, spells out the importance of an automated optical inspection machine for a manufacturing company. For further information, please feel free to get in touch with your AOI equipment provider in Malaysia.

Contact Us

Cortex Robotics Sdn Bhd.

address

72-2-6, Arena Curve, Jalan Mahsuri,

11950 Bayan Lepas, Penang, Malaysia.

T: +604 – 611 0110

E: info@inspiren.dev

social media

quick link