Description

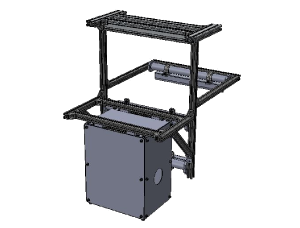

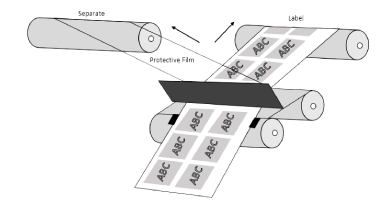

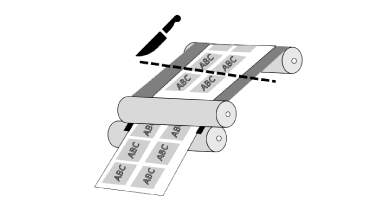

Our AOI Solutions Supported Die Cutting Process

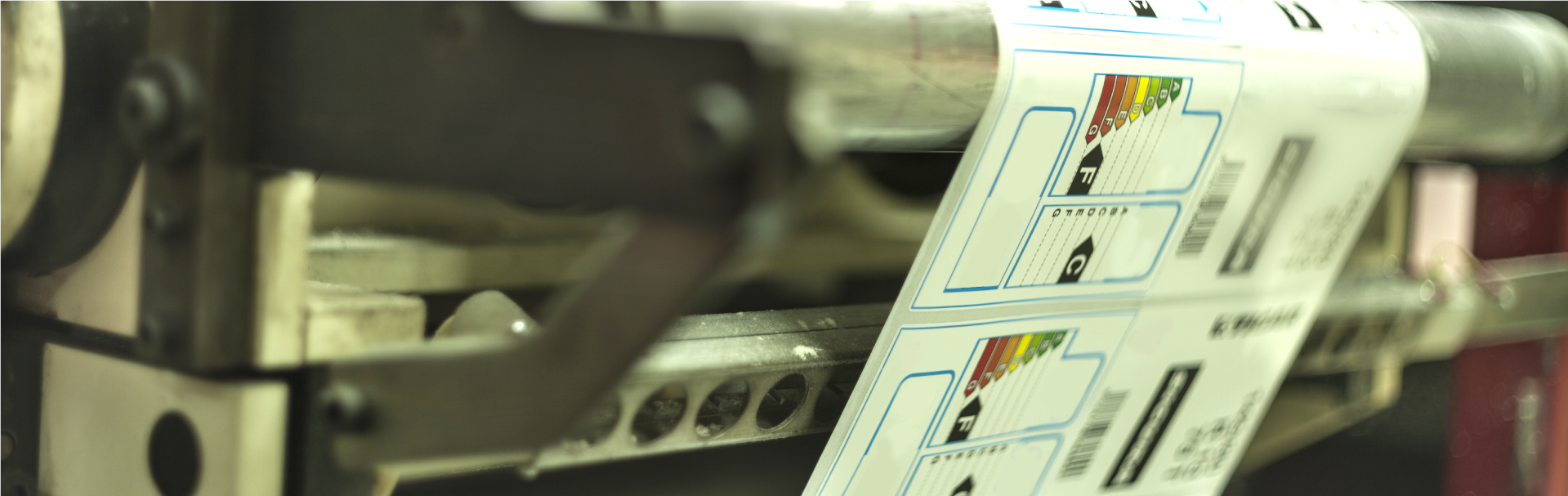

Label Printing

Die Cutting

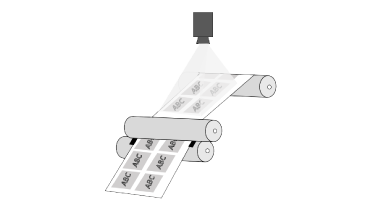

Die-Cut Inspection

ORION SERIES

Die Cut AOI

Orion is a Complete AOI Solutions for the “defects and verification” inspection after die cutting process supporting the printing, packaging, automobile, and mobile phone assembly industry. Popular and reliable solutions for the rapid rise of the die cutting industry.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

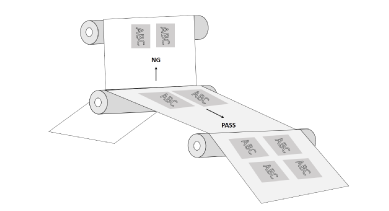

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

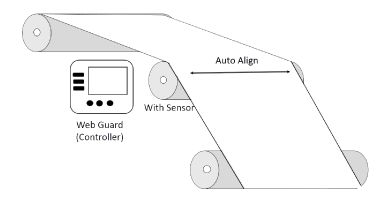

Active Alignment Control

Ensure position is correct before inspection process

Protective Film Peeling

Reduce false call by laminator

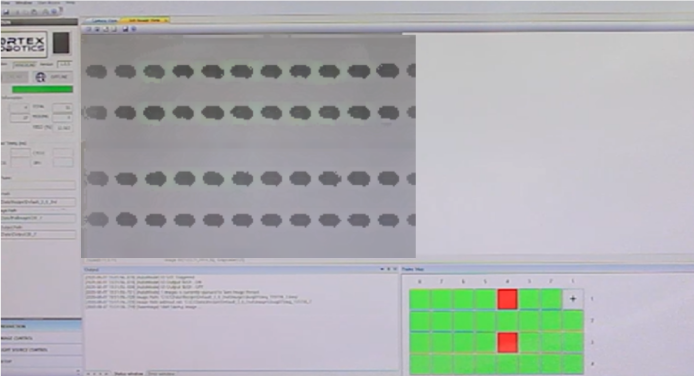

Inspection Station

Continuous high speed 100% vision inspection

NG Remover/ Marking Module

Auto reject removal via dispensing method / vacuum (row)

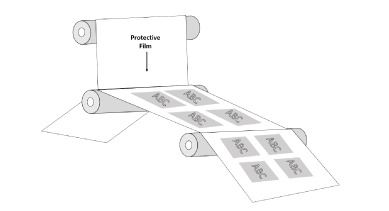

Protective Film Sealing

Auto laminate after inspection to protect labels

Slicing Table

Allow cut off to smaller roll

Reel Traceability via barcode inspection results & image

Other Features

Acceleration & deceleration during start/stop function

Good tape tension control

Fully enclosed inspection area with HEPA positive airflow to prevent contamination

INSPECTION PRODUCTS

Printed Products – various shape/ size stickers, labels

Stamped Sheet – metal, plastics, foam

Translucent / opaque – films, paper, thermal pad

INSPECTION CAPABILITIES

Foreign material, hard scratches, bubble, ASO Adhesive squeeze out, loose burr, height, width, alignment check, incomplete mark, discoloration, broken line, offset