Description

Our AOI Solutions Supported Front-end and Back-end of

Semiconductor Assembly Process

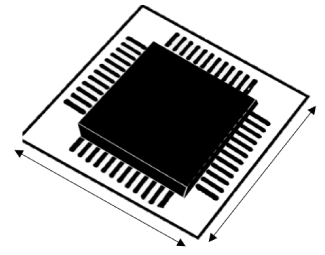

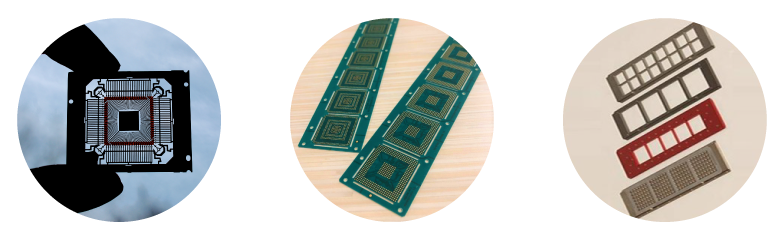

ASI-G2

2D Strip to Strip AOI Inspection

ASI-G2 is a High Speed 2D Strip to Strip AOI inspection solutions with multiple inspection capabilities and low energy consumption solutions.

Its also able to do inspection on various types of leadframe, package and die attach.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects

process

Improve Reputation

Less defects products

increase customer

satisfaction

Low Energy Consumption

For greener earth

Reduce Wastage

Defects can be detect

at the earlier stage

Save Time & Cost

Process can be simplify and

less labour cost

24 hours operation

Maximize production yield

RoHS Compliance

Component

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

Inspection cover each unit of

products without miss

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

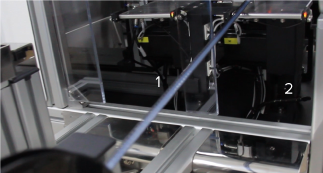

Dual Scan Capabilities Top & Bottom Inspection

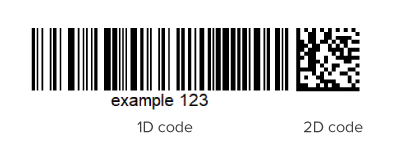

1D & 2D Reading

Fine detection to 2 mils defects

Line Scan 8K, 12K, 16K Camera Capabilities

Other Features

Single software with multiple inspection recipe

Network connectivity for output to server

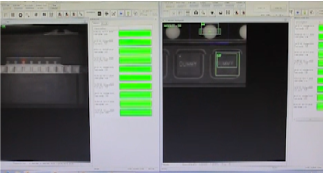

Defect mapping with images

Optional Features

Laser marking system

Able to perform offline verification without disturbing the on-going process

2D code reading

NAS Storage Solution

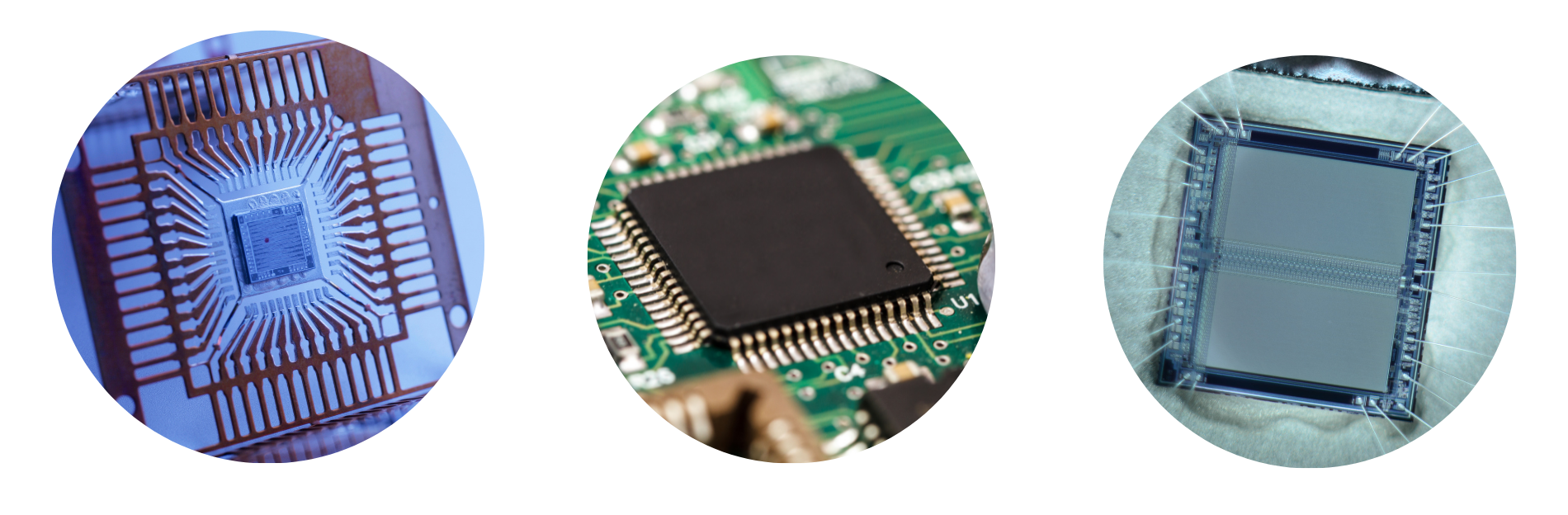

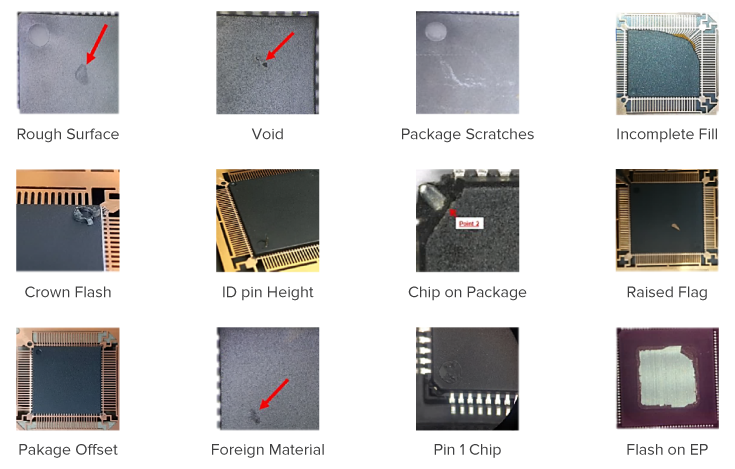

INSPECTION PRODUCTS

Package, Leadframe, Die Attach

INSPECTION CAPABILITIES

Mark & Cosmetics inspection – Rough surface, void, package scratches, incomplete fill, crown flash (2D), ID Pin Height, Chip on package, raised flag, package offset, foreign material, pin1 chip, flash on EP and etc

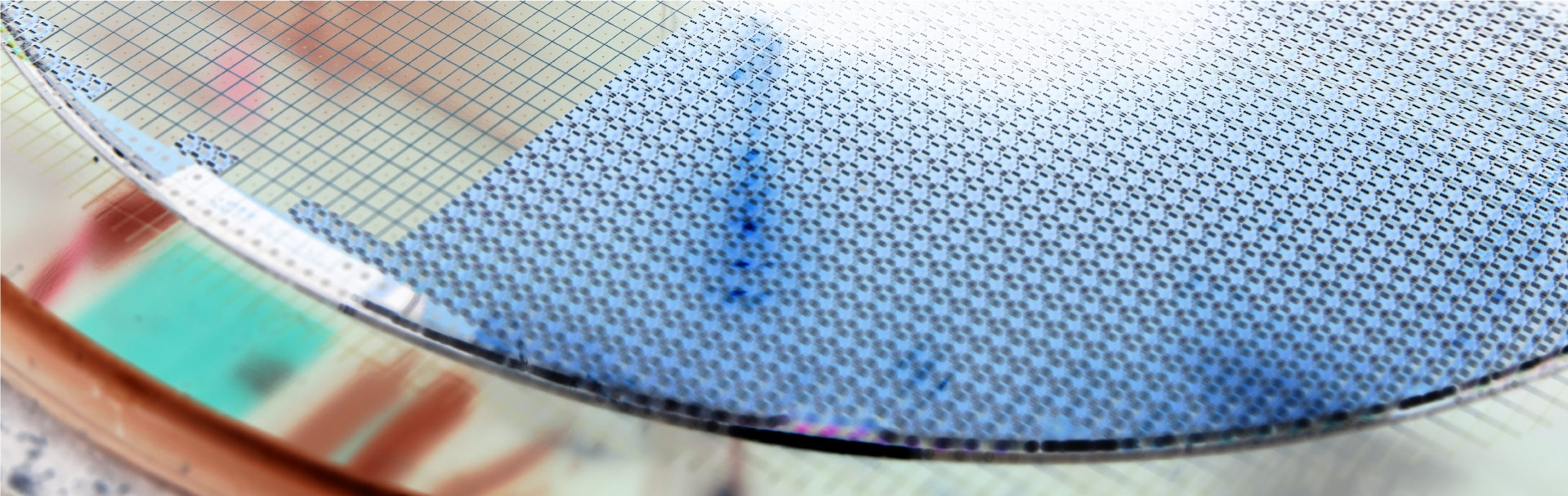

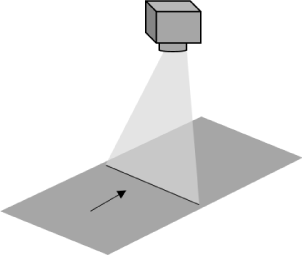

WFi-3X SERIES

High Performance Wafer AOI Inspection

WFi-3X is a series of HIGH PEFRORMANCE Wafer AOI inspection solutions that automatically detect major or minor wafer defects while providing reliable and precise results. It’s supported various types of wafer in semiconductor, electronics, automotive, and medical, led industry.

Highly rated by top semiconductor supplier in the world.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

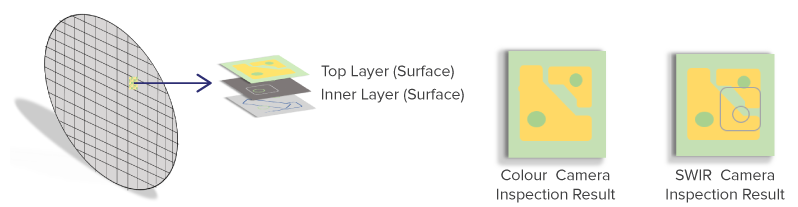

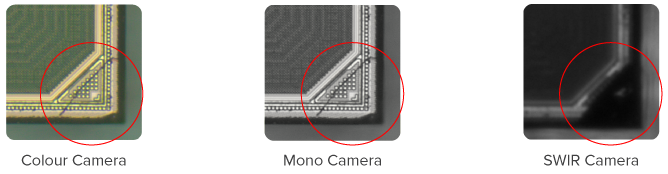

NEW SWIR Camera-Inner Layer Inspection Is Available Now!

Come with Colour Camera. Mono Camera

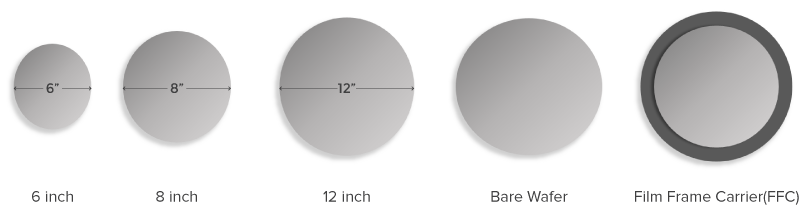

Fitted Wafer Size & Types

Other Features

Dual Fork Robot for quick wafer transition

Auto Teaching recipe setting & Quality Analysis System

Auto-alignment for bare wafer, orientation check

Auto focus on height with auto focus camera and motorized objectives lens

Able to perform offline verification without disturbing the on-going process

Stable machine structure with granite table to prevent vibration

Optional Features

Marking

Bottom Inspection

Semi-Auto or Fully Auto

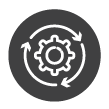

INSPECTION CAPABILITIES

Chipping, Cracks, Stains, Blistering, Scratches, lifted metal, meandering, damaged bump, un-separation, 0ff set –cut, foreign material and etc

*In order to protect our customer design, drawing act as illustration purpose only. Contact us for more information

AVIT Series

2D Tape & Reel AOI Inspection

AVIT is a powerful High-Speed Tape and Reel AOI Solutions that capable to inspect fine defects.

Its support various pocket width of tape and reel.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

Dual Track Operation

Autosave failed defect images

Fine detection to 4 mils defects

Line Scan 8K, 12K, 16K Camera Capabilities

Other Features

Single software with multiple inspection recipe

Network connectivity for output to server

Defect mapping with images

Optional Features

Laser marking system

Offline Programming

2D code reading

NAS Storage Solution

INSPECTION PRODUCTS

Tape & Reel

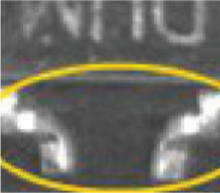

INSPECTION CAPABILITIES

Scratches, chipping, wrong marking, wrong orientation, foreign material and lead bend

Scrtach

Chip Out

Wrong Marking

Wrong Orientation

Foreign Material

Lead Bend

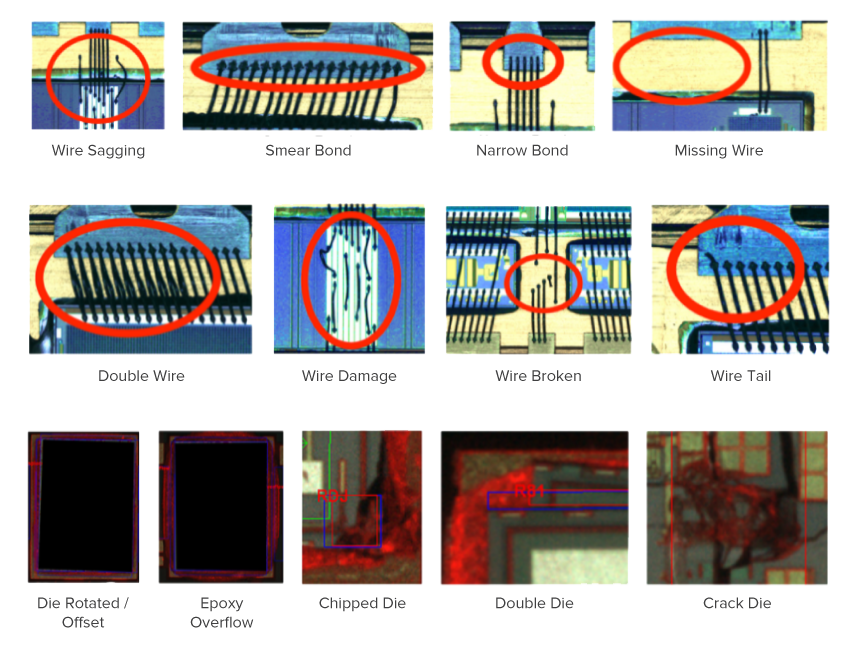

WB-G2

High Precision 2D Wirebond AOI Inspection

WB-G2 is a High Precision 2D Wirebond AOI inspection solutions equip with the latest & high specification technologies which able to perform a smarter and high accuracy inspection on a very fine wirebond. Its also able to do inspection on various types of substrate, leadframe and pallet. Widely used by top semiconductor supplier in the world.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

Inspection cover each unit of

products without miss

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

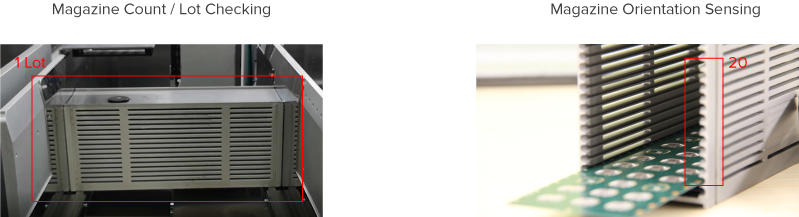

Multiple Magazine Conveyor

1D / 2D / RFID Magazine Reader

Other Features

Quality Analysis System

Generate Report

E-Map

High-Resolution Camera & Auto focusing

8 to 1 Centralised Verification System

SECSGEM Compatible

Auto frame width Adjustment

Able to perform offline verification before reject

Optional Features

Reject Modules (inking, sorter & laser marking)

Bottom inspection

Long Term Storage (up to 3 months)

Offline Teaching

INSPECTION PRODUCTS

Substrate, Leadframe and Pallet

INSPECTION CAPABILITIES

Wire short, wire broken, wire sagging, wire sweeping, torn bond, wire missing, double-bond, lifted wire, lifted ball, ball dimension, particle on die, die off set, epoxy overflow, lead bent, lifted stitch