Description

Diya Series

Glass Top AOI

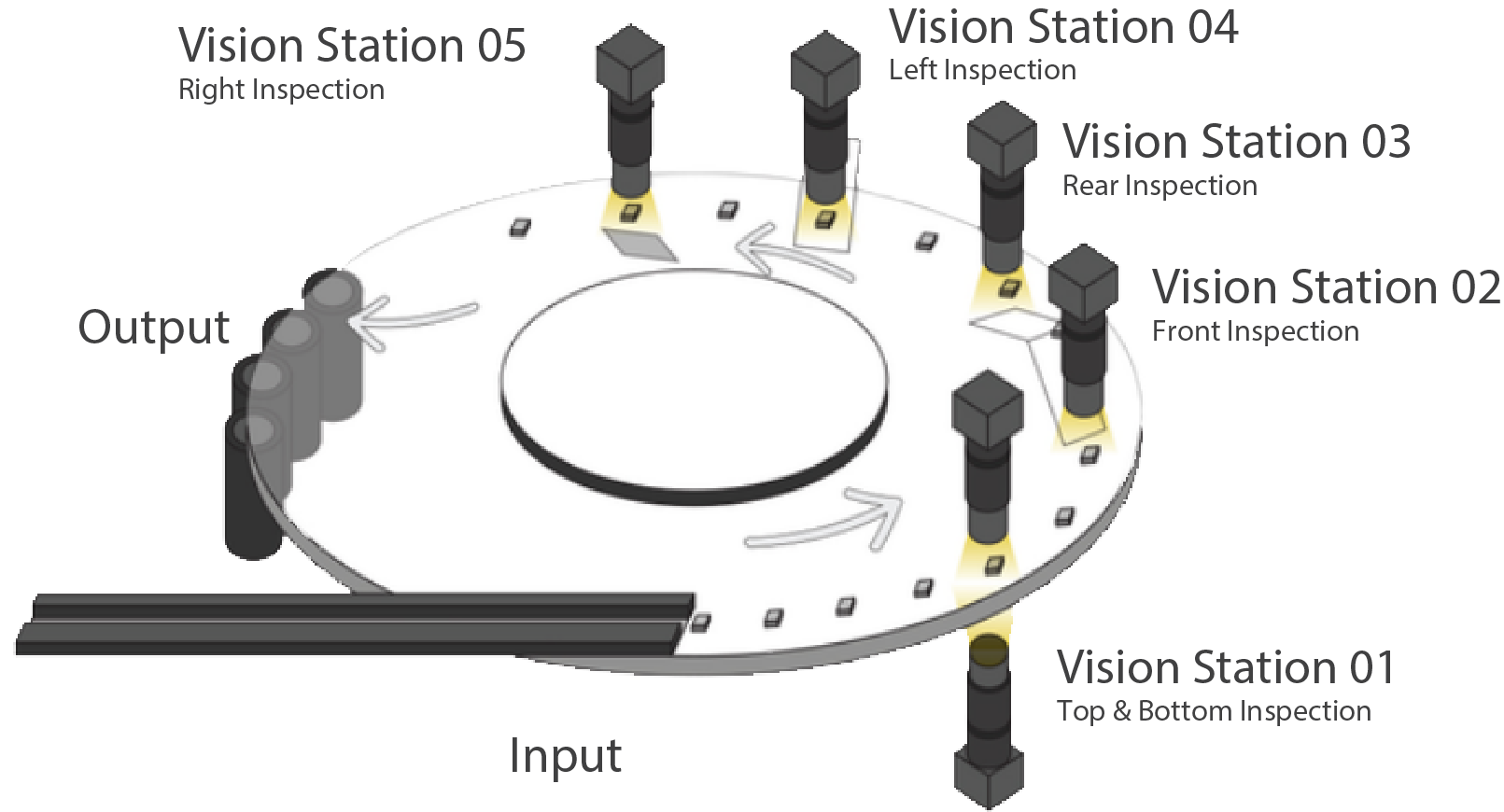

Diya is a 6 Sided High Speed On-The-Fly Automatic Optical Inspection machine. The vision system has a familiar GUI, features realtime display of image acquisition & defects inspected. It allow user to quickly setup & inspect customer’s product from the vibrator bowl. This machine adopted some new approach/methods in inspection, so to cover the widest defect list while providing highest output yield.

Supporting all types of industries.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

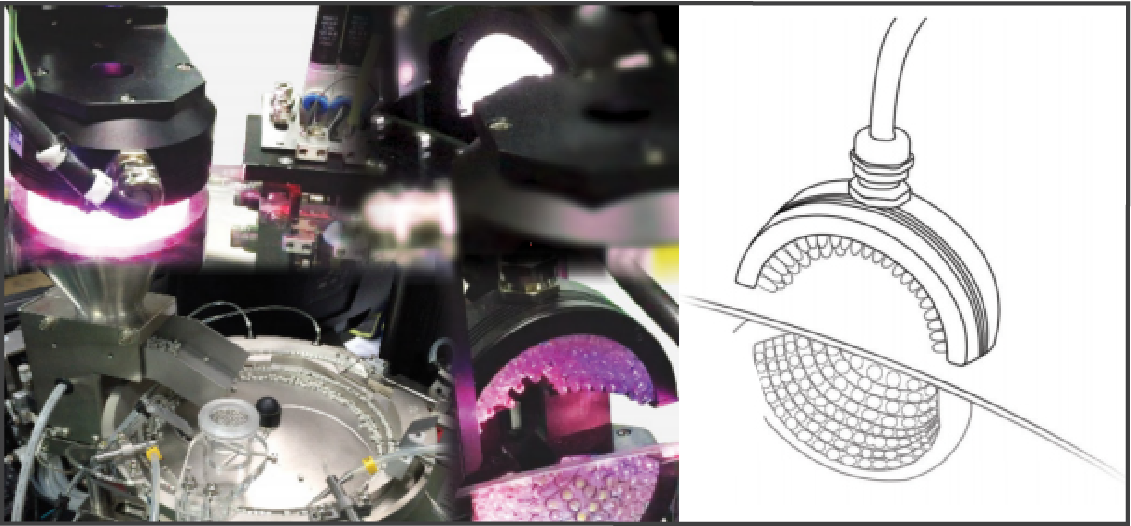

LED Lighting

(Strobe. Fully Configurable, Multi Angle, 8 Channel)

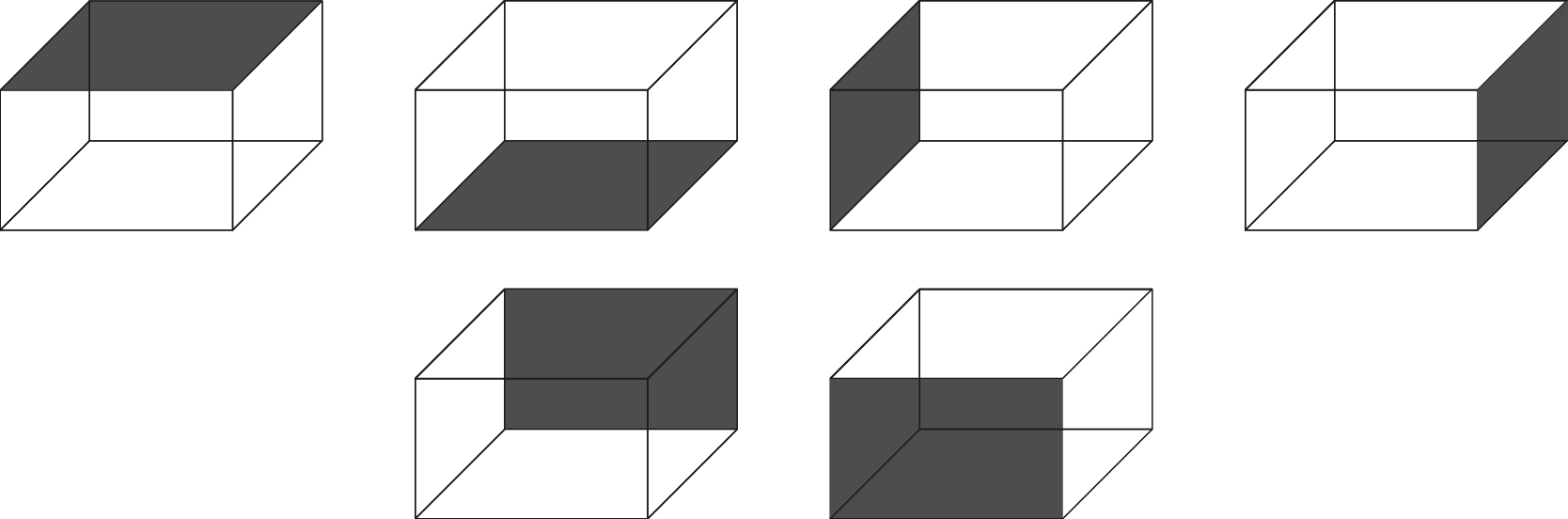

Surface Coverage

Dual image with different illumination setup for broader defect detection

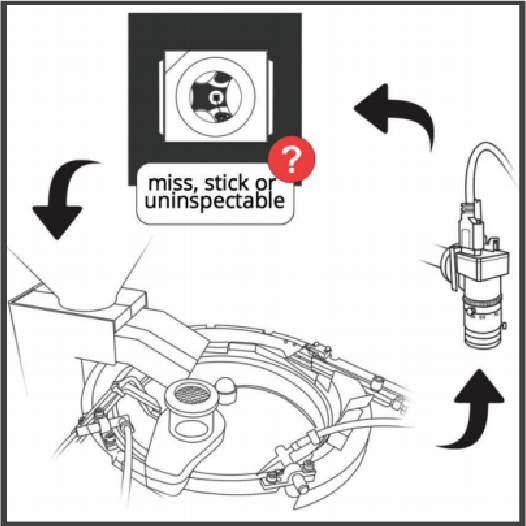

System reject unit is recycled back to the vibrator bowl

Optional Features

1D Barcode Reader

Ionizing Fan

Multiple Monitor Display

Offline Setup Station

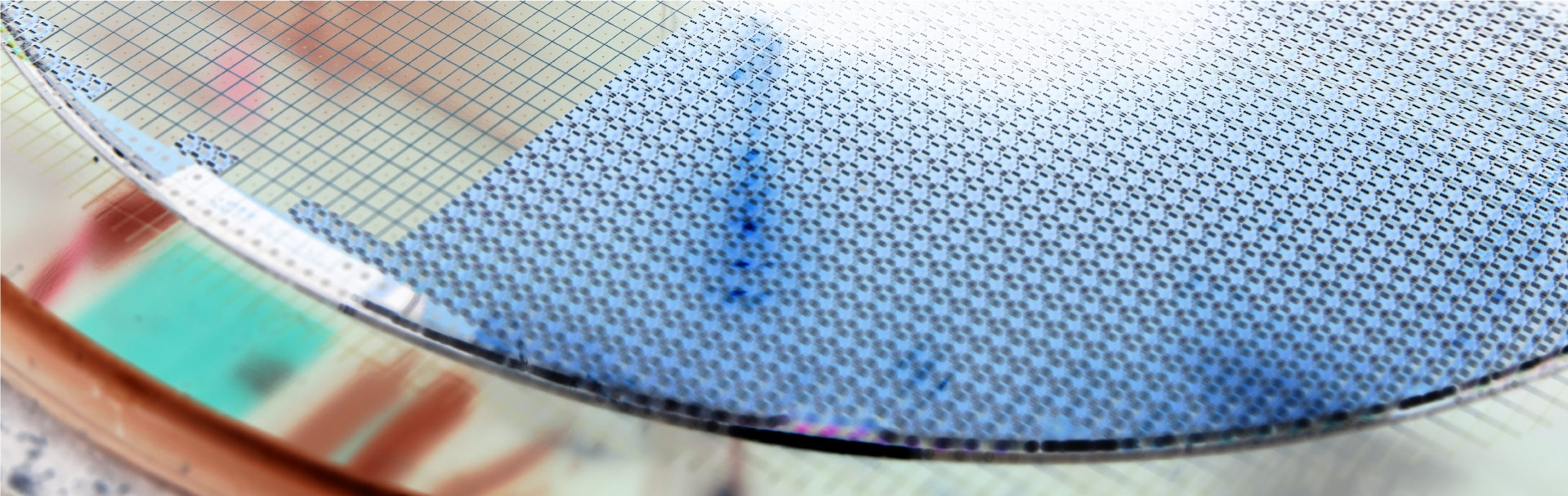

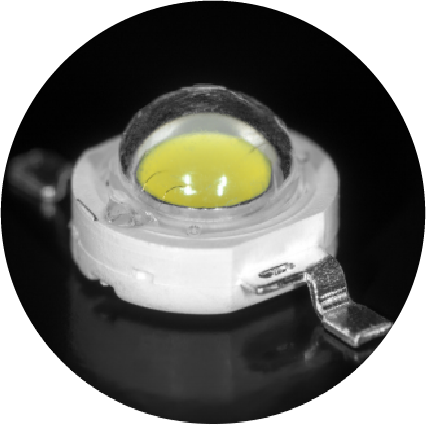

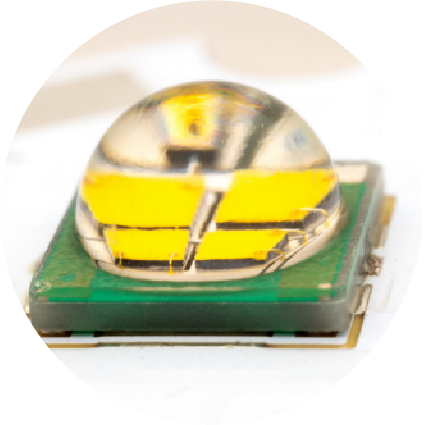

INSPECTION PRODUCTS

Optoelectronics Products and Semiconductor Products, Singular Pieces Products

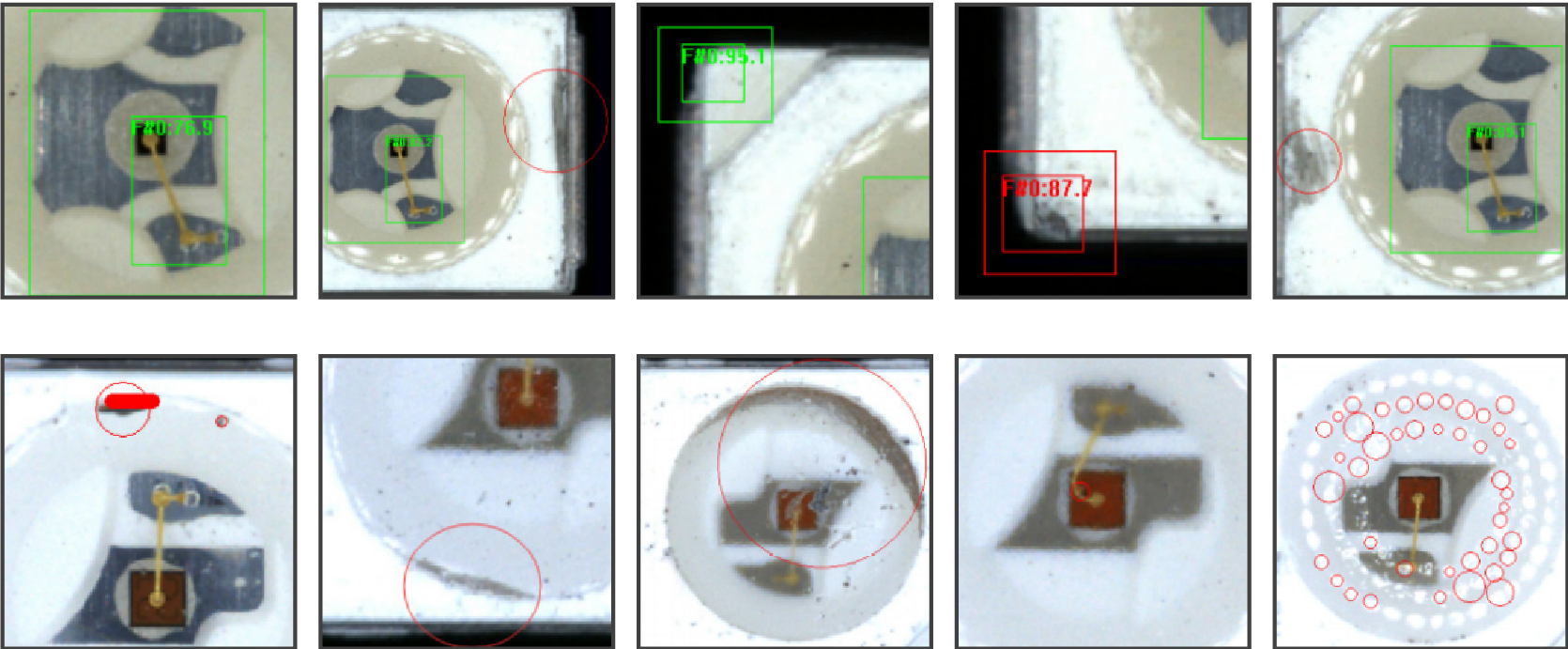

INSPECTION CAPABILITIES

| Item | Specification |

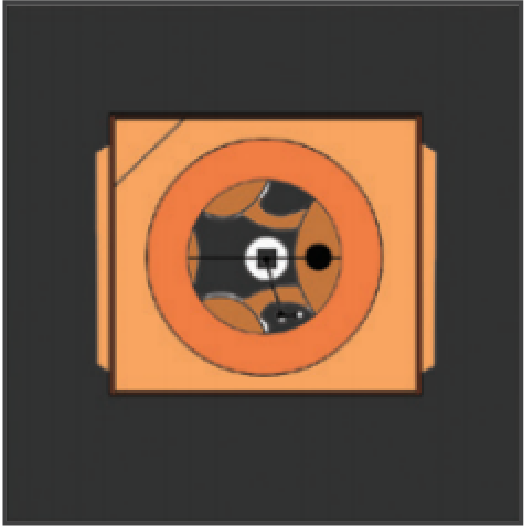

| LED Inspection Capability | Top Surface Chipped Package, No Marking, Marking Alignment, Incomplete Mark, Double Mark, Contamination Bubble, No Resin, Excess Resin (Overfill), Mix Device, Mixed Color, Limited Die & Wirebond Detection Bottom Surface Lead Related Defects, Package Chipping, Damage, Resin Overflows, Contamination Side Surface Lead Relared Defects, Package Chipping, Damage Contamination |

| Software Features | Auto Fail Image Saving, Inspection Results Logging, Multi-user Password Control, Remote Support |