Description

ASTRA SERIES

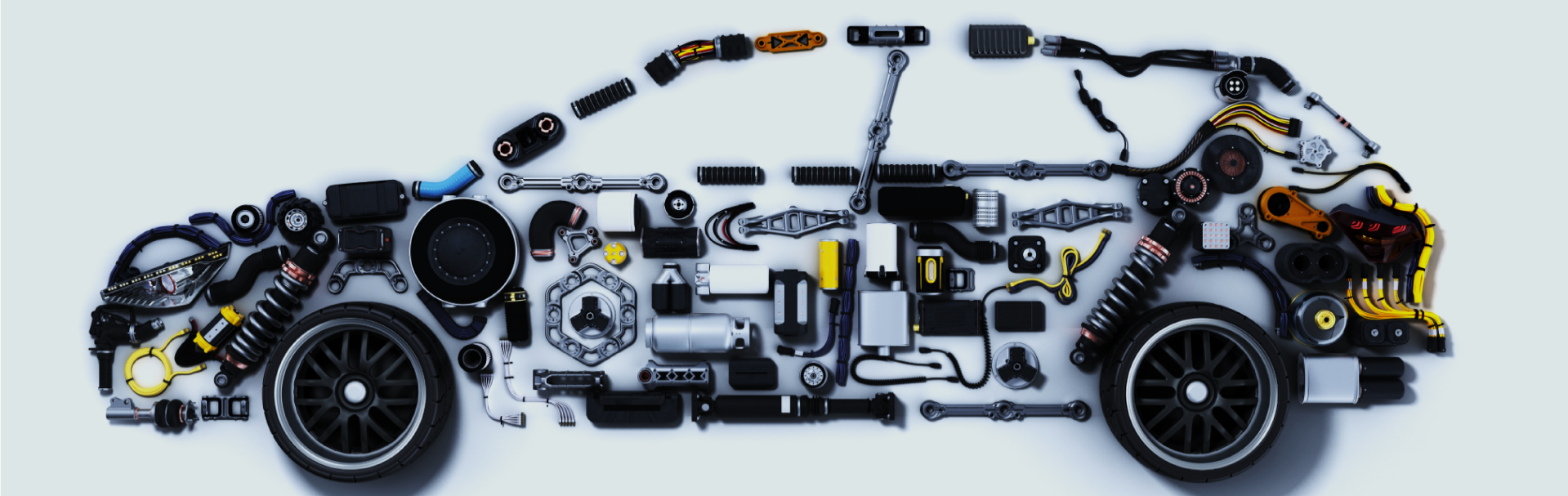

Automotive Component

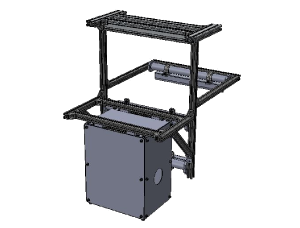

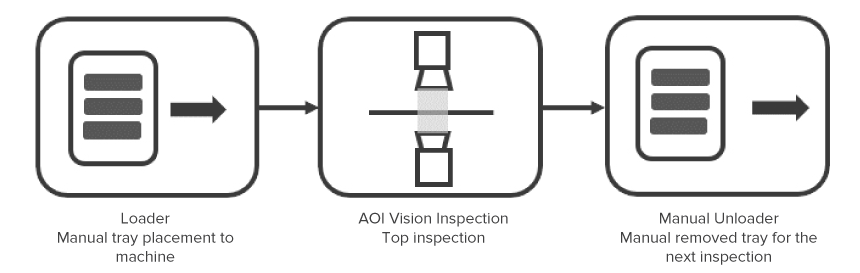

Astra-AOI, is a perfect inspection solution for automotive parts inspection, especially the complex and high-quality parts produced using plastic injection molding. Our smart inspection software has the capability to inspect a wider range of plastic injection defects with more accurate and reliable inspection results compare to human inspection. It is able to support different types of product inspection with different types of customized trays with only a few steps of recipe change. The manufacturer has the choice to upgrade their inspection process to fully automated by connecting it to their production line or semi-automated by manually loading the parts to the tray to inspect.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

Customized Tray to fit your inspection products

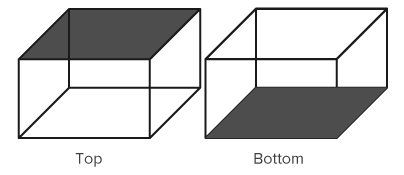

Top & Bottom Inspection

Multiple Zoom Inspection

Colour & Mono Inspection

Semi – automated Inspection

Other Features

Traceability defect image & unit log for verification

Support Offline/ Off-site Programming

E-Mapping to match tray capacity

Generate Report for data analysis

INSPECTION PRODUCTS

Critical automotive parts such as Car key rob, fascia, emblem and etc

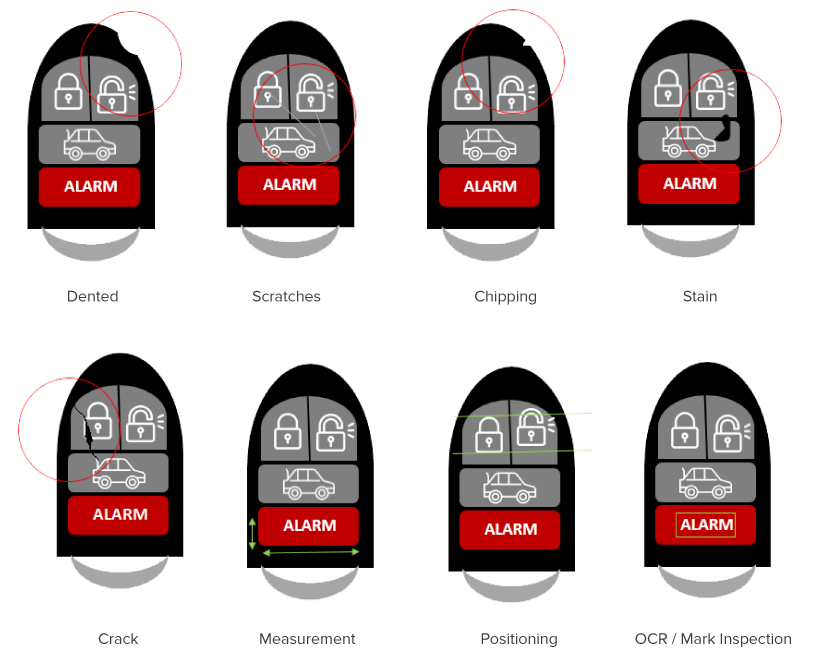

INSPECTION CAPABILITIES

| Surface cosmetic Inspection | dented, contamination, crack, chipping, scratches, stain, fisheye, fiber |

| Silkscreen Printing Inspection | excess, incomplete printing, missing printing, particle, poor printing, smearing |

| 3D measurement + flatness & thickness | diameter flatness, height & width, pitching, positioning, thickness |