Description

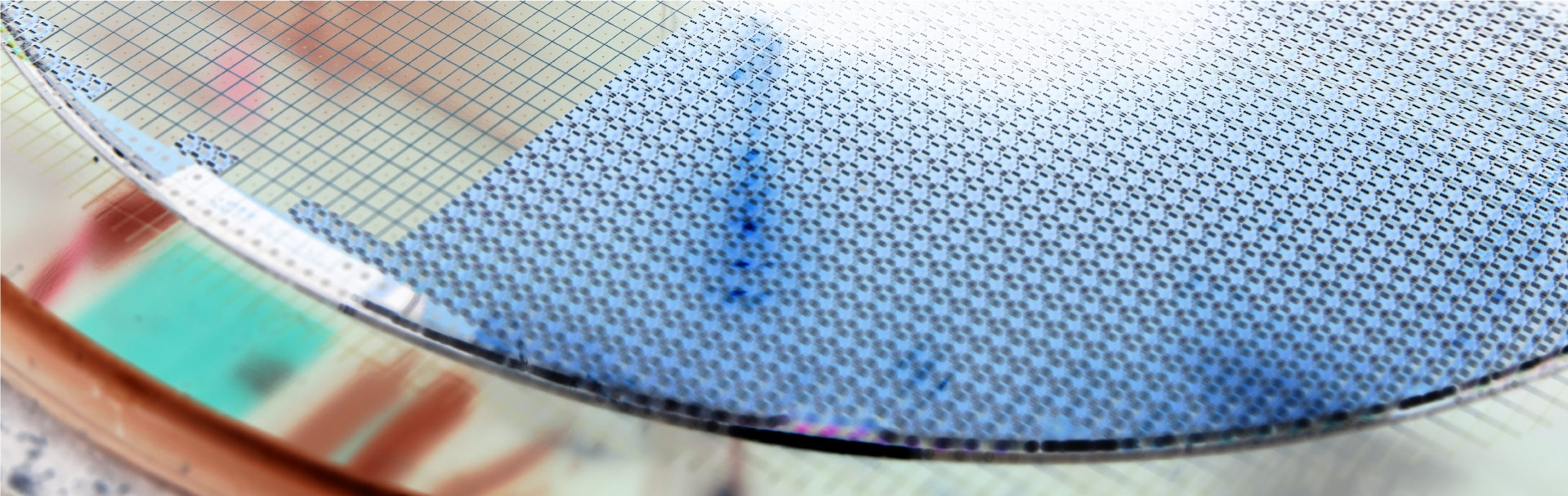

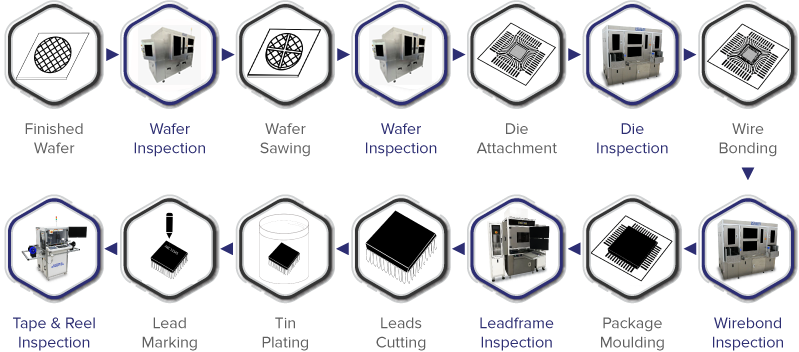

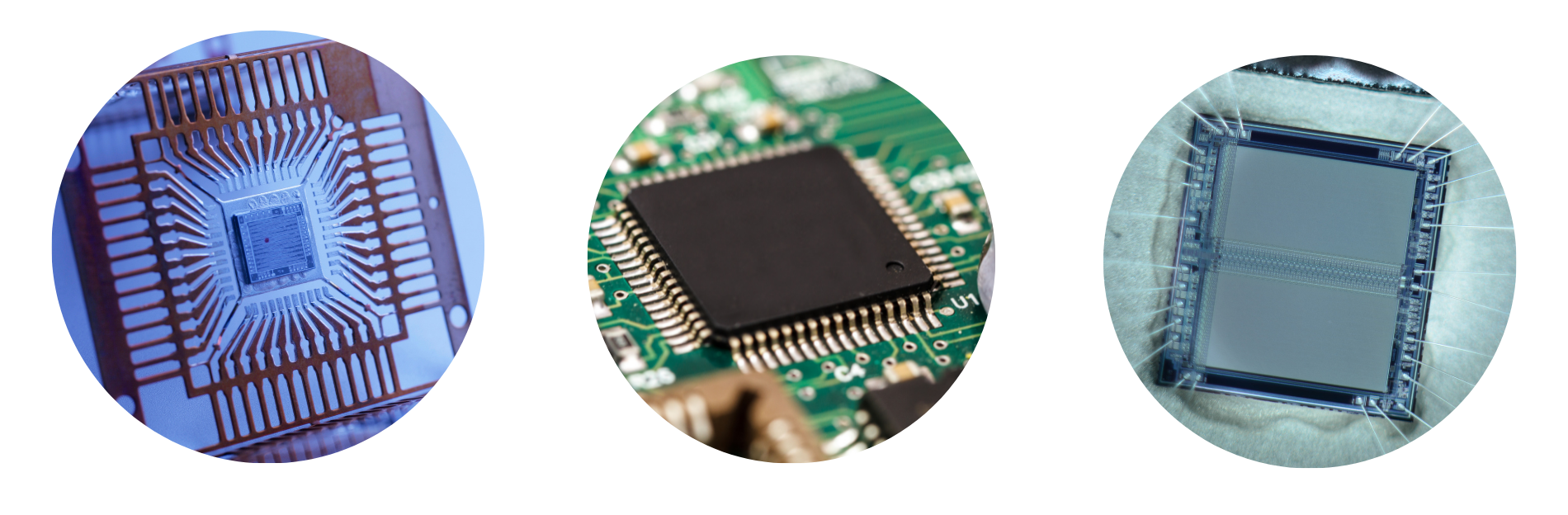

我们的 AOI 解决方案支持半导体后端制造流程

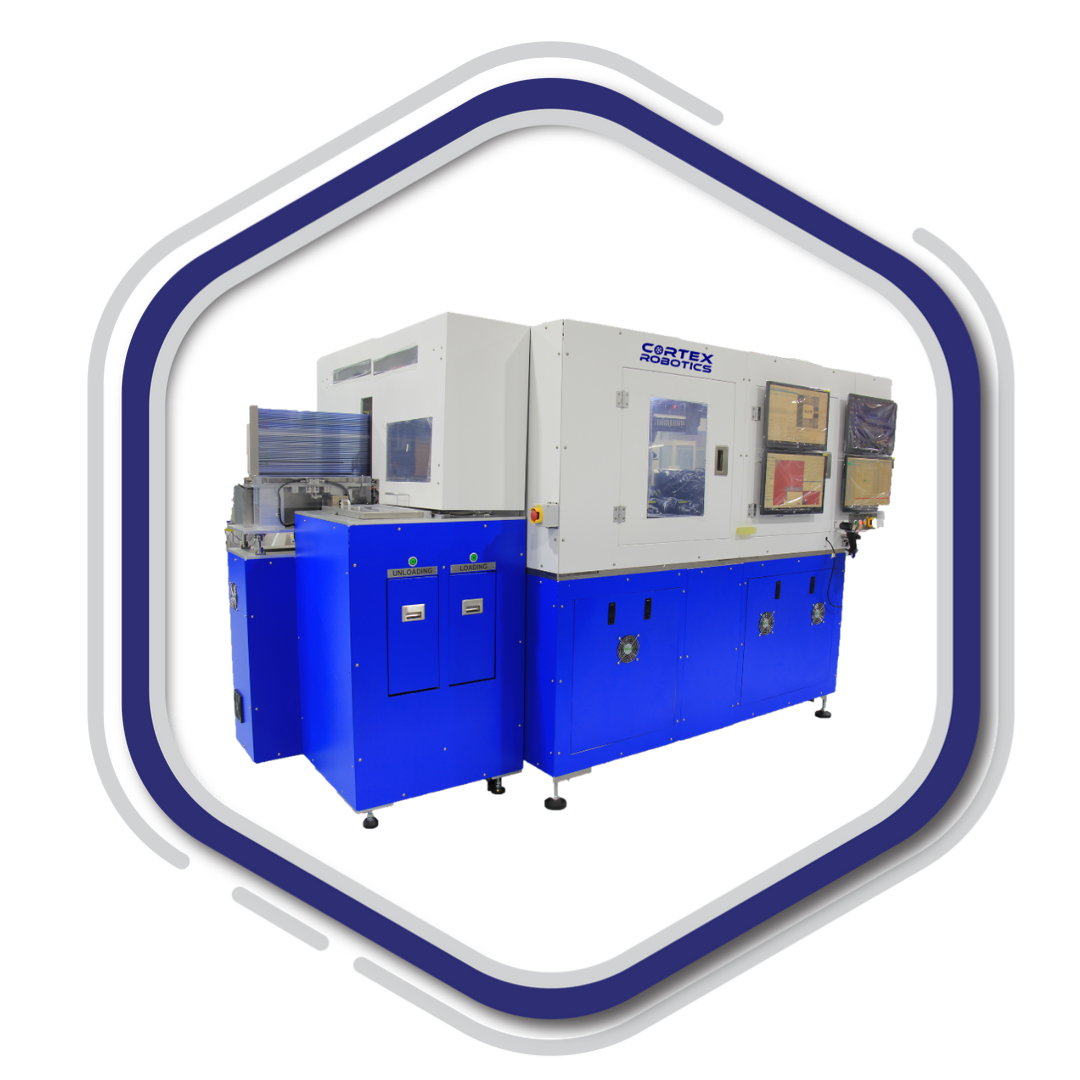

阿尔法系列

高性能晶圆切割前后检测

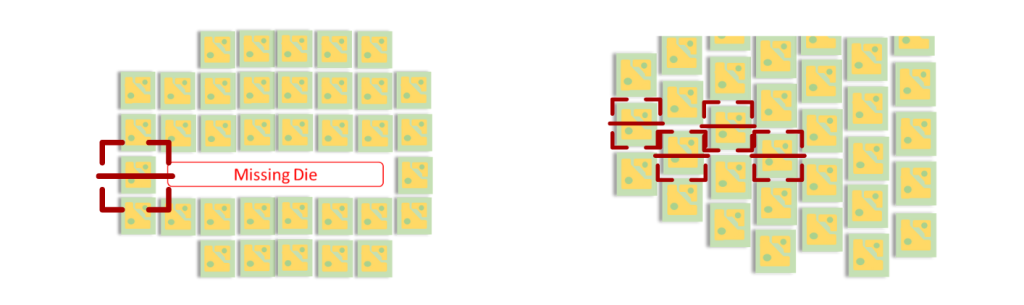

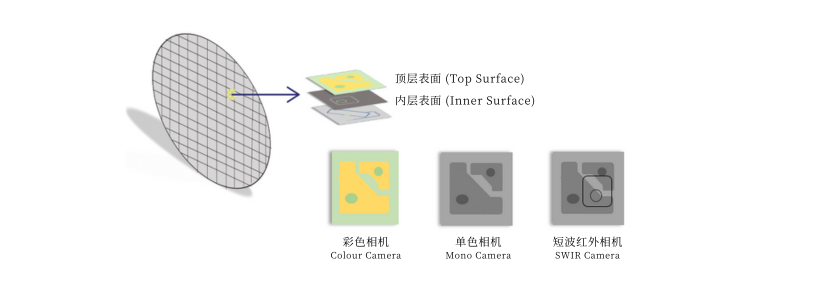

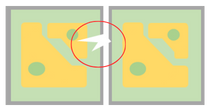

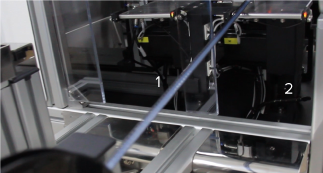

阿尔法系列是高性能晶圆 AOI 解决方案。这些先进的系统旨在自动识别和分类晶圆切割过程后出现的主要和次要缺陷,从而提供可靠且高度准确的缺陷分析。 我们的晶圆 AOI 系列的最新版本引入了 SWIR 技术,检测能力显着增强。 这种短波红外技术已被集成到系统,能够检查半导体芯片的内层和侧壁,从而增强了我们检测这些关键区域的缺陷的能力。 这种基于 SWIR 的新型晶圆检测解决方案得到了升级硬件和软件组件的支持,旨在优化和加快晶圆转换和检测流程。

AOI 检测优点

给商务

完整解决方案检

查、标记、排序

提高质量

快速识别和修复缺陷流程

提高公司声誉

减少产品缺陷可提高客户满意度

减少浪费

可以在早期阶段发现缺陷

节省时间和成本

流程可以简化并减少劳动力成本

24小时运作

提高产量

给用户

检查覆盖各单位产

品不容错过

数据采集

启用跟踪和数据分析

一台AOI机

多种缺陷检测

方便使用

简单的说明手册,带有自己的配方设置

可靠的结果

一致的检验标准

100% 自动化流程

替代人工检查

特点

最小缺陷检测尺寸 - 0.5um

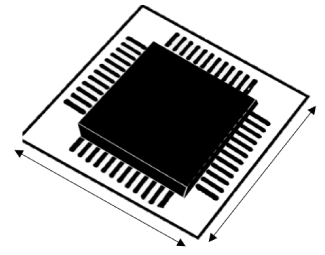

最小芯片检测尺寸300umx300um

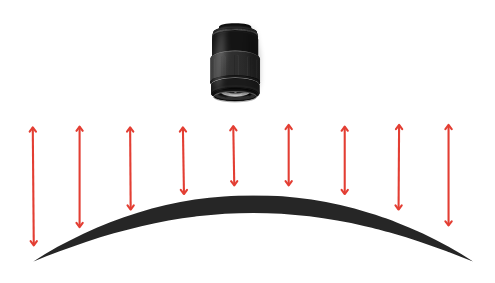

自动聚焦(产品翘曲补偿)

可以适应晶圆图档 (比如Klarf, XML等)

实时检测结果显示

自动晶圆图定位

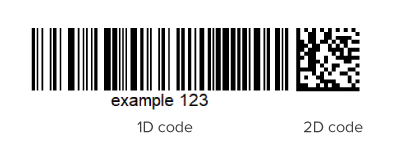

二维读码器

带电离空气和真空的自动门

SECSGEM 兼容

可选特点

去除模块

拒料前支持在线或离线验证

底部多视图检测

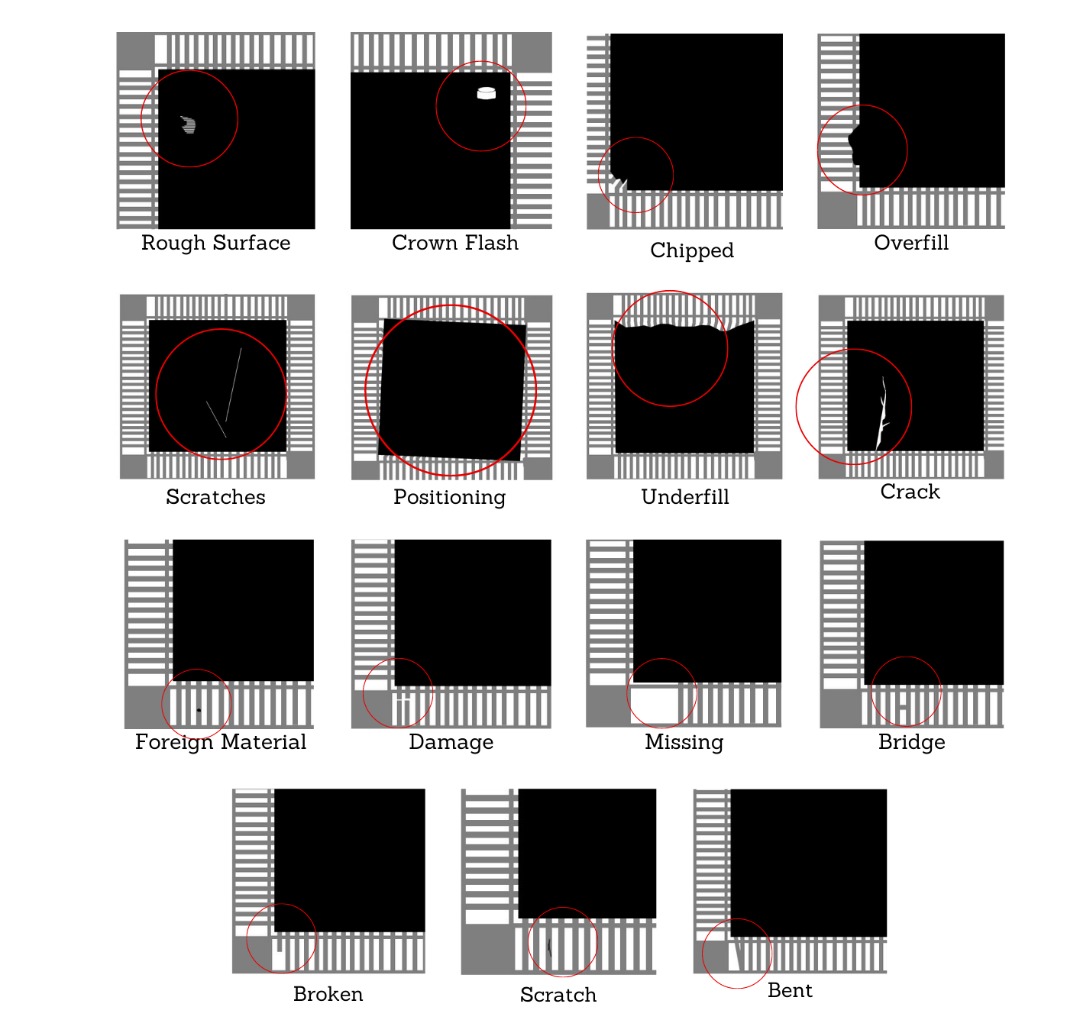

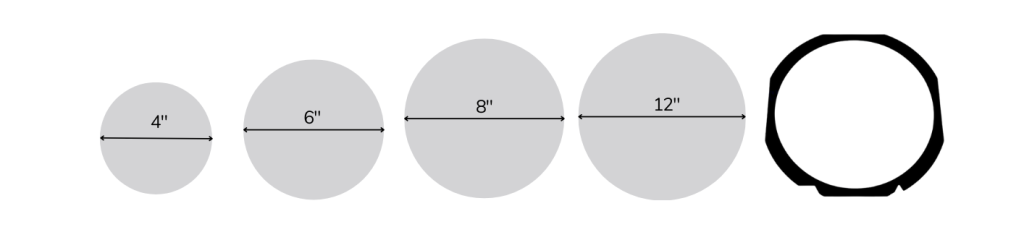

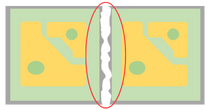

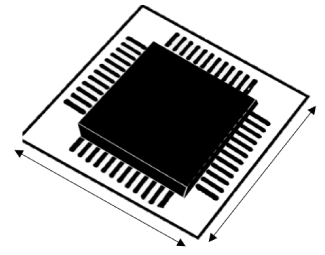

检测范围

*为了保护我们的客户设计,绘图仅用作说明目的。 联系我们获取更多信息

ELECTRA SERIES

Tape & Reel AOI Solutions

Electra is a powerful High-Speed Tape and Reel AOI Solutions that is capable to inspect fine defects.

Its support various pocket width of tape and reel.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

Dual Track Operation

Autosave failed defect images

Fine detection to 4 mils defects

Line Scan 8K, 12K, 16K Camera Capabilities

Other Features

Single software with multiple inspection recipe

Network connectivity for output to server

Defect mapping with images

Optional Features

Laser marking system

Offline Programming

2D code reading

NAS Storage Solution

INSPECTION PRODUCTS

Tape & Reel

INSPECTION CAPABILITIES

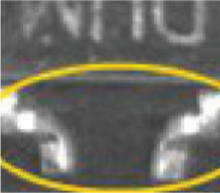

Scratches, chipping, wrong marking, wrong orientation, foreign material and lead bend

Scratch

Chip Out

Wrong Marking

Wrong Orientation

Foreign Material

Lead Bend

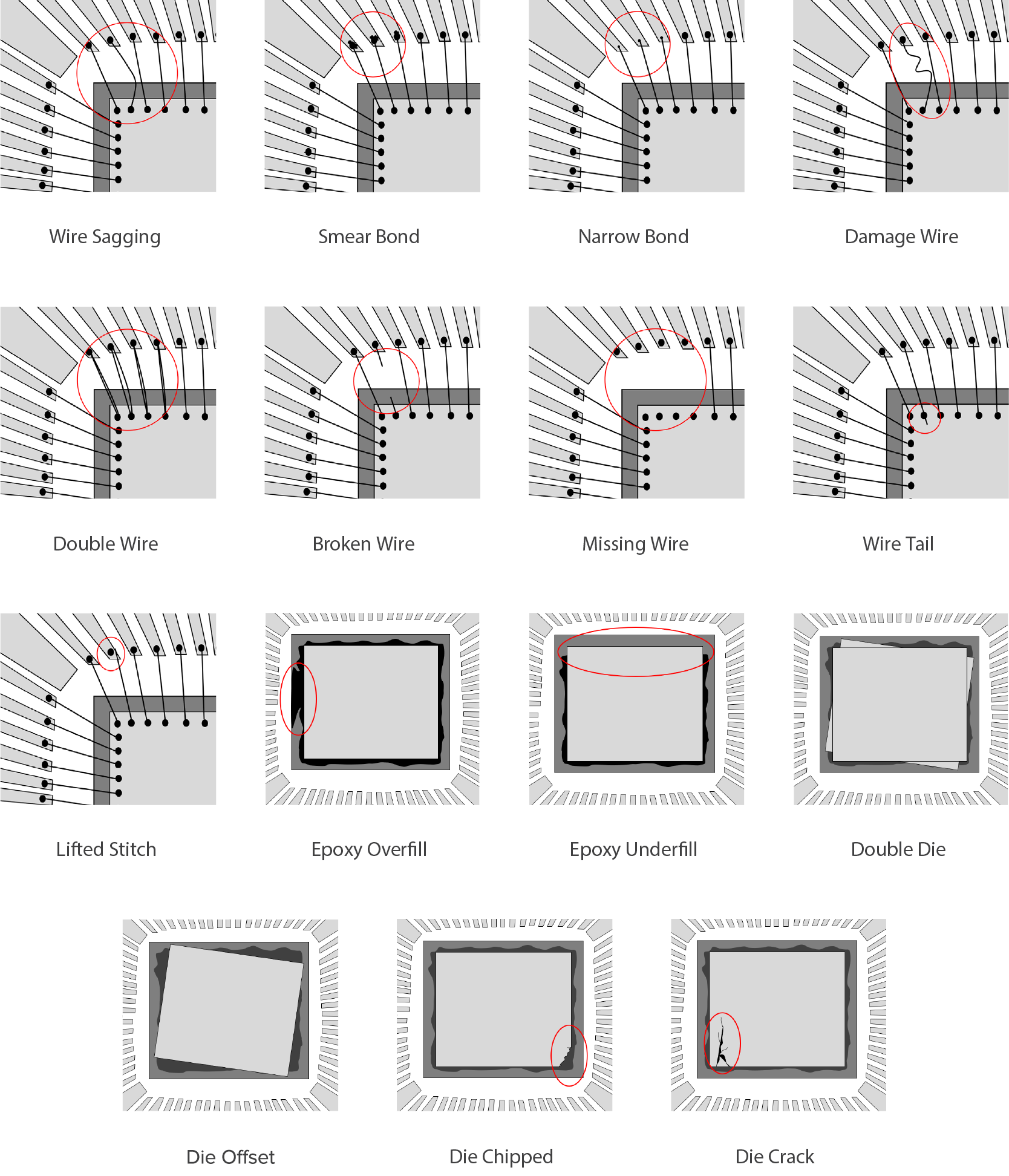

VEGA SERIES

High Precision 3D Wirebond AOI Solution

Vega is a High Precision Wire bond Inspection (AOI) solution equipped with the latest & high-specification 3D technologies which able to perform a smarter and high accuracy height measurement inspection on the die and on wirebond. It’s designed to support inspection before and after the wire-bonding process. It has the capability to inspect the top and bottom of the 3 types of products (Leadframe, Substrate & Pallet) with only a few steps of recipe change. The 3D Wire Bond Inspection has the ability to detect not only the common wire bond defect but also defects such as wire drop, die tilt, and more. It comes with a multi-choice of reject modules that suit your need, for example, laser marking, laser cutting, inking, and Pick&Place.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects process

Improve Reputation

Less defects products increase

customer satisfaction

Reduce Wastage

Defects can be detect at the earlier

stage

Save Time & Cost

Process can be simplify and less

labour cost

24 hours operation

Maximize production yield

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

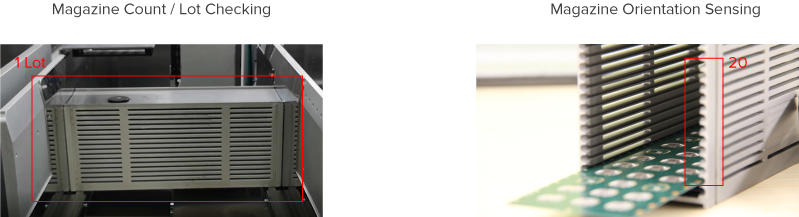

Multiple Magazine Conveyor

1D / 2D / RFID Magazine Reader

Other Features

Quality Analysis System

Generate Report

E-Map

High-Resolution Camera & Auto focusing

8 to 1 Centralised Verification System

SECSGEM Compatible

Auto frame width Adjustment

Able to perform offline verification before reject

Optional Features

Reject Modules (inking, sorter & laser marking)

Bottom inspection

Long Term Storage (up to 3 months)

Offline Teaching

INSPECTION PRODUCTS

Substrate, Leadframe and Pallet

INSPECTION CAPABILITIES

Wire short, wire broken, wire sagging, wire sweeping, torn bond, wire missing, double-bond, lifted wire, lifted ball, ball dimension, particle on die, die off set, epoxy overflow, lead bent, lifted stitch

MIRA SERIES

Strip to Strip AOI Solutions

Mira is a High-Speed Strip to Strip AOI solution with multiple inspection capabilities and low energy consumption solutions.

Its also able to do inspection on die attached and various types of leadframe and package.

BENEFITS OF AOI INSPECTION

To Business

Full Solution

Check, Mark, Sort

Increase Quality

Quick identify & Fix defects

process

Improve Reputation

Less defects products

increase customer

satisfaction

Low Energy Consumption

For greener earth

Reduce Wastage

Defects can be detect

at the earlier stage

Save Time & Cost

Process can be simplify and

less labour cost

24 hours operation

Maximize production yield

RoHS Compliance

Component

To User

Inspection cover each unit of

products without miss

Data Collection

Enabling tracking & data analysis

One AOI Machine

Multiple types defects inspection

Easy Control

Simple Instruction manual with

own recipe setting

Reliable Result

Consistent inspection criteria

100% Automatic Process

Replace manual inspection

Key Features

Dual Scan Capabilities Top & Bottom Inspection

1D & 2D Reading

Fine detection to 2 mils defects

Line Scan 8K, 12K, 16K Camera Capabilities

Other Features

Single software with multiple inspection recipe

Network connectivity for output to server

Defect mapping with images

Optional Features

Laser marking system

Able to perform offline verification without disturbing the on-going process

NAS Storage Solution

INSPECTION PRODUCTS

Package, Leadframe, Die Attach

INSPECTION CAPABILITIES

Mark & Cosmetics inspection – Rough surface, void, package scratches, incomplete fill, crown flash (2D), ID Pin Height, Chip on package, raised flag, package offset, foreign material, pin1 chip, flash on EP and etc