BLOG

What Are The Common Defects Of A Semiconductor

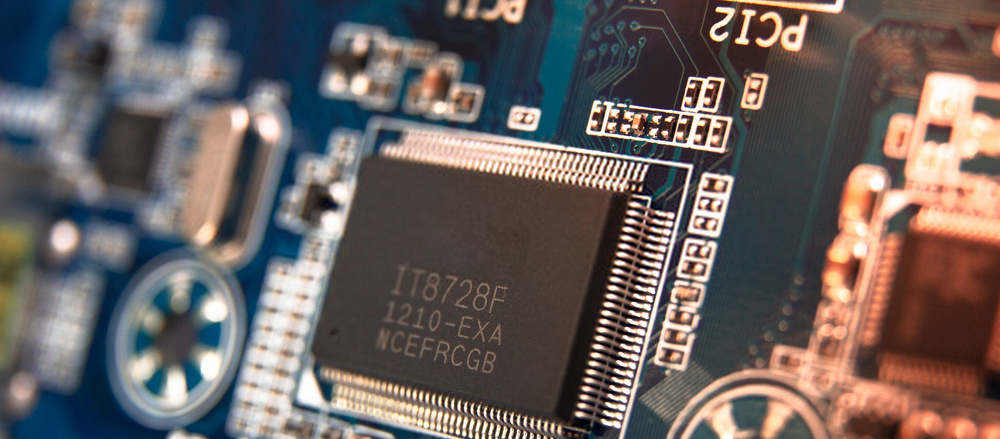

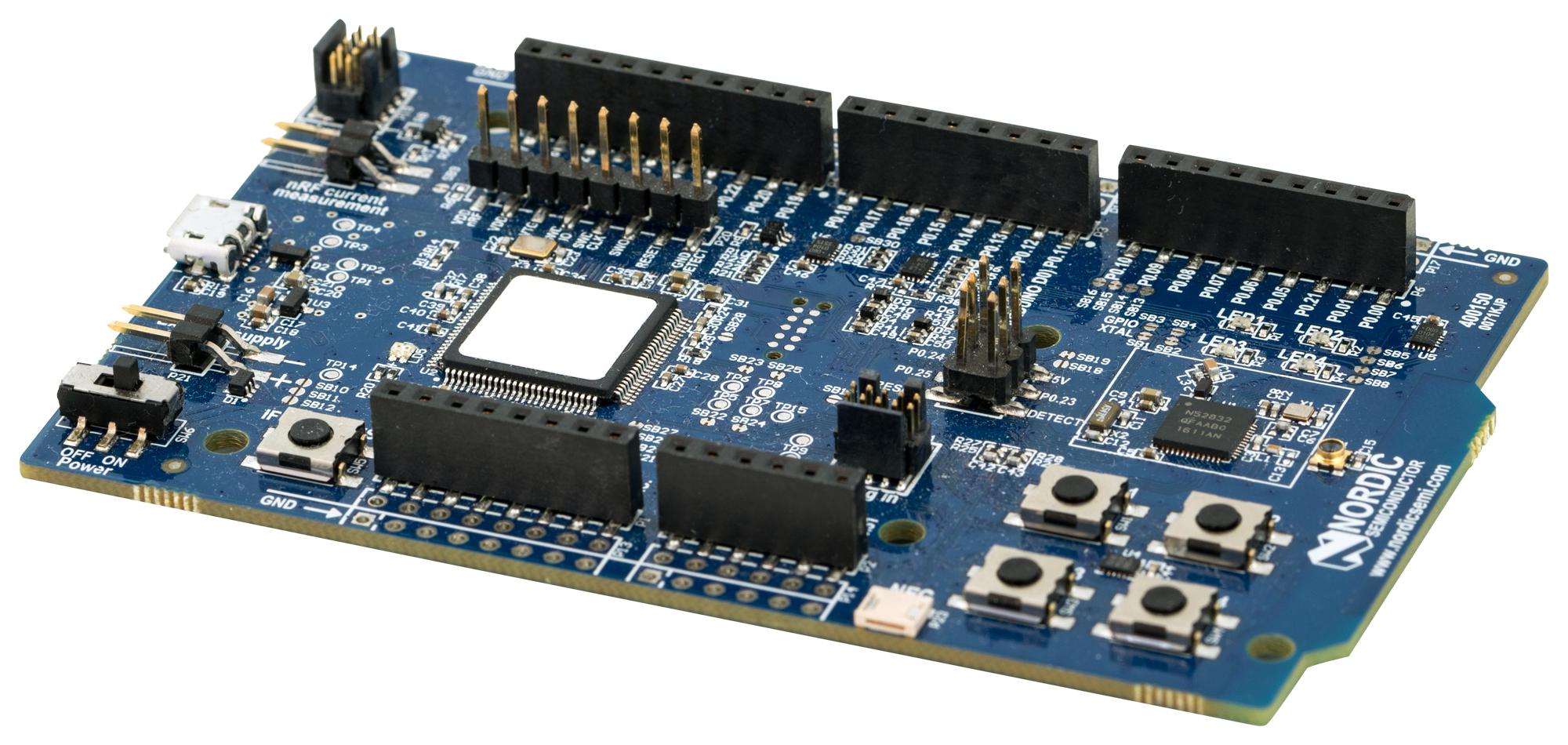

Most of the electronic gadgets we come across every day are equipped with semiconductors. A semiconductor is a material product that consists of silicon, which is a good electrical conductor that conducts electricity greater than an insulator like glass, but less than a pure conductor, like aluminium and copper.

The conductivity of an insulator and a semiconductor can be changed by the introduction of impurities (doping) to attain certain requirements of the electronic gadget it is implanted in.

Also known as semis or chips, semiconductors are used in several products like computers, smartphones, appliances, gamin hardware, medical equipment etc.

Semiconductor devices boast of several beneficial properties like showing variable resistance, transmitting current more easily in one lane than the other and being sensitive to heat and light.

The main functions of a semiconductor are signal amplification, the transformation of energy, etc. Thus, this product is utilized in several industries around the world.

Types of semiconductors

Generally, semiconductors consist of four primary product categories:

1. Memory

Memory chips act as a temporary warehouse of data and transmits information to and from the brains of the computer. Over the years, the memory market has blossomed, leading to a decrease in the prices of memories. Only a few giants such as Toshiba, Samsung, and NEC chose to remain in the game even with the dwindling prices of memories.

2. Microprocessors

Microprocessors are CPUs that consist of simple logic to carry out certain tasks. Intel has dominated this segment and forced other competitors to flee and lay their roots into a smaller niche or a different segment.

3. Commodity integrated circuit

Commodity integrated circuits can also be referred to as “Standard chips.” These circuits are often manufactured in large quantities for routine processing. This segment is mainly dominated by huge Asian chip producers, and it yields minimal profits that only the prominent semiconductor companies can compete for.

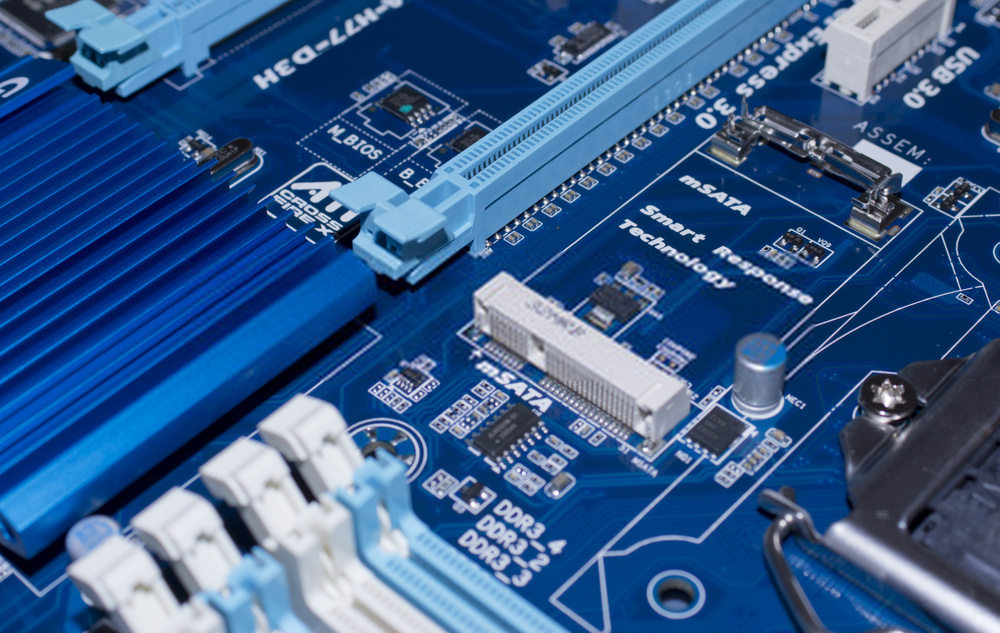

4. Complex SOC

The SOC (System on a chip) is mainly about producing an integrated circuit chip with the capacity of an entire system on it. In today’s digital world, the market rotates around a rising demand for consumer products that are affordable and comes with new features. With the dwindling memory, microprocessor, and commodity integrated circuit market, SOC is the only one left with the best chance to attract a huge amount of companies.

Defects in semiconductors

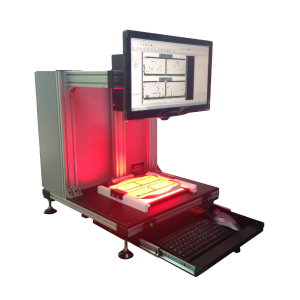

Semiconductors have some defects, and each of these defects can be detected with the aid of some detection techniques like the use of an Aoi machine, die inspection, etc.

The first type of defect that can be found in a semiconductor is associated with the material used. Due to the fact that the device solely depends on the precise makeup of the chip, any impurity found in this device will damage its function. Discovering these variances isn’t an easy task, but it can be done with the aid of automated optical inspection and other inspection techniques.

Another defect might not be related to the material used but with its mechanical integrity. Cracks on the semiconductor which are caused by stresses can make it malfunction. A problem like this can be detected with the use of dye penetrant testing and acoustic microscopy.

The third type of defect can be caused by some defective electronic present in the chip. Tracking these defective electronics is hard because most components and techniques choose to adopt indirect tactics to examine the package.

For instance, a technique such as curve tracing is used to determine the change in the chip’s output from the anticipated output of a functional chip. Afterwards, hotspot detection is then utilized through microthermography techniques to take note of heat regions that can help in tackling the issue. There are also several techniques within microthermograpy that can detect the fault.

Takeaways

The defects in a semiconductor are caused by several factors. Detecting these defects can be a hard process, but with the right technique, the job can be done effectively and faster. One of these techniques, which is the use of a vision inspection system, can effectively detect some of the defects present in a semiconductor.

Other techniques are the automated optical inspection technique, die inspection technique, etc. The introduction and the use of these techniques has led to a major boost in the semiconductor industry. Identify these defects and more by getting your own Automated Optical Inspection (AOI) solution from us!

Contact Us

Cortex Robotics Sdn Bhd.

address

72-2-6, Arena Curve, Jalan Mahsuri,

11950 Bayan Lepas, Penang, Malaysia.

T: +604 – 611 0110

E: info@inspiren.dev

social media

quick link